Introduction

Flange is a piece for connecting pipes and other equipment to each other, which is usually used in piping systems. This connecting part is produced in different types such as weld neck, socket weld, blind and spectacle for use in refineries, power plants, etc. Their material can be made of Carbon steel, Stainless steel, Alloy steel, Aluminum, Copper and Plastic.

the standards for making flanges include: ANSI, ASME, JIS, DIN, EN. According to the mentioned cases, the price of this piece also depends on factors such as the dimensions, the type of raw materials and the standard used, etc. In the continuation of this article, we will examine the types of flanges, technical specifications, how to engrave, dimensions, classes, standards, methods of producing flanges, technical specifications table based on ASME B16.5 standard and the factors affecting their prices. You can also download its PDF file at the end of this article.

Last update: 11/13/2024 | Approximate study time: 20 min

- 1 Introduction

- 2 Flange

- 3 Gasket

- 4 Flange production methods

- 5 Cast Flanges

- 6 Forged Flanges

- 7 Cutting Flanges

- 8 Flange technical specifications

- 9 Stamping Flange

- 10 Flange classification

- 11 Classification based on ANSI/ASME standard

- 12 Classification according to ISO standard

- 13 Classification based on API standard

- 14 Sizes

- 15 Classes

- 16 Materials

- 17 1- Carbon Steel

- 18 2- Alloy Steel

- 19 3- Stainless Steel

- 20 4- Nickel Alloys

- 21 5- Aluminum

- 22 6- Polyethylene

- 23 Type Of Flanges

- 24 Types of flanges based on the connection method

- 25 Types of flanges based on face

- 26 Flange standards

- 27 1. ASME B16.5 Standard:

- 28 2. ASME B16.47 Standard:

- 29 3. EN 1092-1 Standard:

- 30 5. JIS B2220 Standard:

- 31 Technical Specification Table

- 32 Diameter table of flanges according to ASME B16.5 standard

- 33 Flange Production

- 34 Flanges Price

- 35 Purchase Flange

Flange

As we said before, a flange is a piece for connecting pipes in industrial piping. Of course, we should know that they are also used in the medical systems of hospitals, fire departments, etc. Bolts and nuts are used to connect these parts to each other as well as other equipment. Flanges are widely used in various industries such as oil and gas, petrochemical, chemical, etc.

Gasket

Gaskets are an element used for sealing between two flanges. They are usually made of composite, metal and non-metal (plastic, aramid fiber and ect). Flat face (FF) flanges are sealed with flat gaskets and also, raised flanges (RF) whose face has serrated surface are sealed with gaskets called spiral wound gaskets.

Flange production methods

Cast Flanges

Another method of flange production is casting. In this method, molten metal is inserted into a pre-made mold. Then, after cooling, it is machined into the final shape. But the produced parts may have a vacuum and also have less strength than the forging method.

Forged Flanges

In this method, tools such as hammer, hydraulic press and ring rolling are used to produce flange. Due to the pressure applied and hammering to the metal object, finally the manufactured part will have high resistance and there will be no vacuum in it.

Contact the sales department (central) for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Cutting Flanges

The production process of cutting flange begins with smoothing the steel metal, which thins the material by means of rollers to reach the thickness of the desired plate. Then the outer diameter and inner diameter of the flange (except the blind flange) are cut using a torch, laser or water jet cutter (water pressure). The necessary screw holes and teeth are cut. Also, the flange is also machined according to the exact specifications. The flanges produced in this method have a lower production cost, but they leave more material waste and their strength is weaker than other methods.

| Cast Flanges | Forged Flanges | Cutting Flanges | |

|---|---|---|---|

| Cost | Middle | High | Low |

| Strength | Middle | High | Low |

| Tolerance | Low | High | Middle |

| Material waste | Middle | Low | High |

| All kinds of materials and sizes | High | Middle | Low |

Flange technical specifications

Stamping Flange

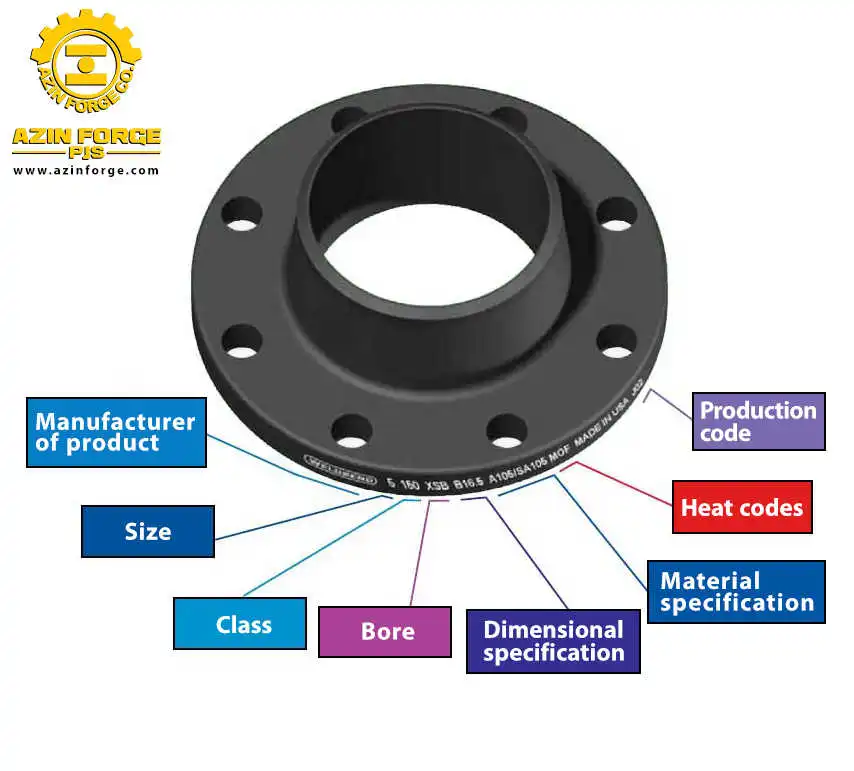

1- Manufacturer of Product: for example, AzinForge

2- Flange Dimension: According to ASME B16.5 standard, it can be between 1/2 inch and 60 inches (AzinForge also produces non-standard flanges according to customer requests).

3- Class: In the sense of pressure determination, it is the allowable temperature that can be tolerated for the use of a flange.

4- Bore Diameter: if there is a hole on the flange, it is engraved on it.

5- Dimensional specifications: For example, the ASME B16.5 standard has different dimensions, sizes and technical specifications that are used according to the customer’s needs.

6- Material specifications: indicates the type of raw materials used. For example, code A105, which is one of the grades of carbon steel.

7- Heat Codes: This code is engraved in the flange to determine the material specifications and tolerable temperature. Also, this code is displayed in alphanumeric form.

8- Product code: It is optionally engraved by the manufacturing companies to inquire about the flange.

Flange classification

Classification based on ANSI/ASME standard

In this standard, flanges are classified by class. These classes include: 150, 300, 400, 600, 900, 1500 and 2500. The numbers shown indicate pressure based on pounds per square inch (psi).

Classification according to ISO standard

The pressure tolerance in this standard is indicated by the symbol PN, which means Nominal Pressure in Bar. For example, PN20 indicates a pressure tolerance of up to 20 Bar.

Classification based on API standard

This standard has a higher-pressure tolerance than the ANSI/ASME standard, and its pressure tolerance is indicated by Megapascal (MPa). For example, 69 MPa is equal to 10,000 psi.

Sizes

According to the ASME B16.5 standard, the size of the flanges is from 1/2 inch to 24 inches, and according to the ASME B16.47 standard, the size of the flange is from 26 inches to 60 inches according to its type (AzinForge also produces non-standard flanges according to customer requests)

Classes

Classes in the ANSI/ASME standard include: 150, 300, 400, 600, 900, 1500 and 2500. Also, in the API standard, classes include: 2000, 3000, 5000, 10000, 15000 and 20000. For example, in class 150, if the temperature is 38°C, the tolerable pressure is 285 pounds per square inch (psi), and if the temperature is 538°C, the tolerable pressure is 20 psi. Therefore, higher class flanges can withstand more pressure and are suitable for higher pressure systems or heavier loads.

Materials

The raw materials used in the manufacture of flanges can be varied and are selected depending on the type of application and the required performance conditions.

In the following, we state some common raw materials used in the manufacture of flanges.

1- Carbon Steel

This type of steel is used for many flanges. Also, carbon steel is one of the main materials used in various industries such as: construction, automobile manufacturing, tools and machinery production due to its strong mechanical properties and suitable welding capability.

2- Alloy Steel

Alloy steel is used in flanges that are used under high temperature conditions or special pressures. Especially, this type of steel is strengthened by adding alloy elements such as chromium, nickel and molybdenum.

3- Stainless Steel

Flanges that are placed in environments with high humidity (water and oxygen) may be made of stainless steel. Therefore, this type of steel has high resistance to rust and corrosion.

4- Nickel Alloys

Nickel alloysmay be used in flanges that are exposed to very high temperatures or contact with certain chemicals. Also, these alloys have high resistance to corrosion and high temperature.

5- Aluminum

Aluminum is used in some light flanges with less mechanical resistance. Also, aluminum has features such as: light weight, high thermal conductivity and corrosion resistance. Therefore, aluminum is one of the popular materials for use in various industries such as: automotive, construction, aerospace and many others.

6- Polyethylene

Polyethylene is a type of polymer that is used as a plastic material. Also, this material is widely used due to its properties such as flexibility, resistance to breaking, insulation and chemical resistance. For this reason, this material is widely used in packaging, automotive, electronics and other industries.

Other raw materials such as copper and titanium are also used in some flanges. But choosing the right raw material for the flange should be determined based on its technical characteristics and application conditions.

Type Of Flanges

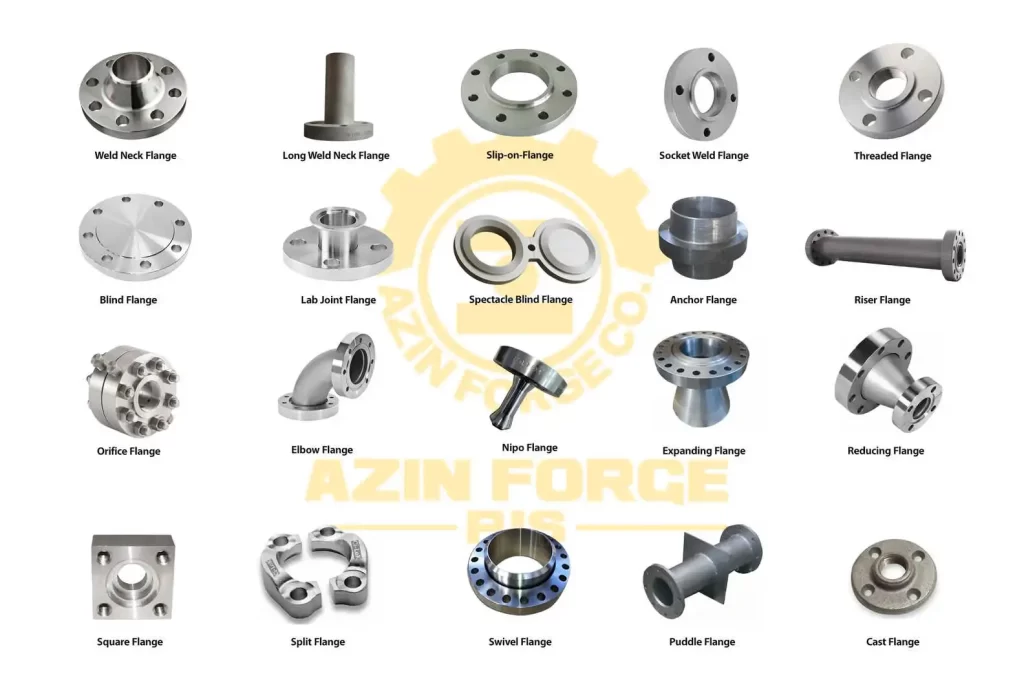

There are two types of flanges: 1-types of flanges based on the connection method and 2-types of flanges based on face, which we will discuss below.

Types of flanges based on the connection method

1- Weld Neck Flange

2- Long Weld Neck Flange

3- Slip On Flange

4- Socket Weld Flange

5- Threaded Flange

6- Blind Flange

7- Lap Joint Flange

8- Spectacle Blind Flange

9- Anchor Flange

10- Orifice Flange

11- Raiser Flange

12- Elbow Flange

13- Nipo Flange

14- Grooved Split Flange

15- Expander Flange

16- Reducing Flange

17- Square Flange

18- Swivel Flange

19- Puddle Flange

20- Cast Flange

1- Weld Neck Flanges

Weld Neck (WN) Flange is one of the types of flanges used to connect pipes or equipment in the piping system. This type of flange has a throat to connect to the pipe or other parts. Due to the extra strength and stability that this type of flange provides, it makes sense to use it in various industries. This piece is used in various industries such as oil and gas, petrochemical and chemical, etc. due to its durability and stability.

2- Long Weld Neck Flanges

Long Neck Welding (LWN) Flange is a piece used in the piping system and as you can see in the picture above, it is the same as the weld neck flange, except that it has a longer neck and is parallel to the pipe. According to the ASME B16.5 standard, this part is available in sizes 1/2 to 24 inches and class 150, 300, 600, 900, 1500 and 2500.

3- Slip On Flange

Slip On (SO) Flange is a type of connector that is used to connect pipes or equipment to each other in industrial piping. Also, this type of flange has a non-flat external disc that is placed on the end of the pipe or equipment and is connected to it by welding. For this reason, it is a quick and easy way to connect pipes, valves, etc. in the piping system. Normally, this piece is used in low pressure applications and is suitable for gas, water and sewage industries and heating and cooling systems.

4- Socket Weld Flanges

Socket Weld (SW) Flange is an industrial piece used to connect pipes and equipment in high pressure and high temperature applications. These flanges are suitable for use in industrial and petrochemical applications due to their ability to withstand high pressure and temperature. Also, this piece is welded directly to the pipe.

5- Lap Joint Flanges

Lap Joint (LJ) Flange has two parts called Stub End and Lap Joint Ring. The stub end is welded and connected to the pipe or other equipment. On the other hand, Lap Joint Ring is connected to the pipe or other joints by means of bolts and nuts. Also, one of the features of this piece is the ability to adjust the angle and position.

6- Threaded Flanges

Threaded Flange is an industrial part that has gear holes that allow them to be connected by screwing. These flanges are typically used in applications that require quick and easy assembly without the need for welding. The use of threaded flanges in various industries has many advantages, including reducing installation and maintenance costs, reducing installation time and increasing the speed of maintenance. According to the mentioned cases, this part is suitable for industries such as petrochemical, oil and gas, chemical industries, etc.

7- Blind Flange

Blind Flange (BL) is an industrial piece that is used to close the end of a pipe or device. These flanges can include three types of internal surfaces such as: Flat Face (FF), Raised Face (RF) and Ring Type Joint (RTJ). Also, these types of flanges can be used for testing, inspection and temporary covering purposes (until the final connection is made).

8- Spectacle Blind Flange

Spectacle Blind Flange is a type of connector that has two parts connected to each other. One part has a blind disc, which is used as a cap to block pipes and other equipment, and the other part has a hole disc, which is used to access fluids in the piping system. This type of flange is usually used for repairs and maintenance of piping systems and piping valves.

9- Anchor Flange

Anchor Flange is used to connect pipes to fixed structures. In this way, it prevents unwanted displacement or movement of pipes. It is used in the piping system due to the tolerance of pressure and vibrations caused by the flow of liquids and gases.

10- Riser Flange

Riser flange is a type of connector that is used to connect two sections of pipe or piping in a vertical direction. It is usually used in stations such as oil and gas, water wells and other industrial processes that require vertical piping. This piece is designed to provide a secure, leak-free connection in the piping system and to withstand high pressure and temperature.

Contact the sales department (central) for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

11- Orifice Flanges

Orifice Flange is a part that is used to connect pipes and industrial equipment as well as to measure the flow of liquids. This piece is circular and has holes on top of it and has a central arm that connects to the top holes to measure fluid flow.

12- Elbow Flange

Elbow flange is a type of connector that is used to connect in the piping system. According to the shape of this part that we can see in the picture above, we understand that it is used for the parts that need to change the direction. Also, this flange has angles such as 45, 90 and 180 degrees.

13- Nipo Flange

Nipo Flange is a connecting part that has two different parts. One part is known as a nipple and the other side has a weldneck flanges. Due to this feature, it is used in connections of different sizes to maintain sealing and no leakage, and it is also used in 90 degree connections.

Types of flanges based on face

Flanges in terms of face include the following:

1- Flat Face (FF) Flange

2- Raised Face (RF) Flange

3- Ring Type Joint (RTJ) Flange

4- Tongue and Groove (T&G) Flange

5- Male & Female (M&F) Flange

1- Flat Face Flange (FF):

This type of flanges has a smooth surface without protrusions. Therefore, Flat Face (FF) Flanges are suitable for applications that require a tight connection and lower pressures.

2- Raised Face Flange (RF):

These types of flanges have a raised face that is connected to other flanges by placing a gasket on them. Therefore, Raised Face (RF) flanges are used for most medium and high-pressure applications.

3- Ring Type Joint Flange (RTJ):

These flanges have an indentation in the form of a ring, in which a ring gasket, which is usually metal, is placed inside to create a tight connection between the pipes. Due to this feature, Ring Type Joint (RTJ) flanges are suitable for high pressure and temperature.

4- Tongue and Groove Flanges (T&G):

Tongue and Groove (T&G) flanges consist of a tongue like raised ring on one flange face and a matching groove on the other face. When two flanges are connected to each other, the tongue of one flange enters the groove of the other flange, and this makes the connection level and stable.

5– Male & Female Flanges (M&F):

Male and female (M&F) flanges are a pair of flanges. One of them is the female, which has an indentation on its inner face and the other is male, which has a protrusion on the inner disk.

Flange standards

In the following, we will mention some of the most important standards of flanges:

1. ASME B16.5 Standard:

This is a standard for steel and stainless-steel flanges set by the American Society of Mechanical Engineers (ASME). Therefore, it includes dimensions and specifications of flanges used in oil and gas, petrochemical and engineering industries.

2. ASME B16.47 Standard:

This standard is used for large, high-pressure steel fittings used in the oil and gas, chemical, petrochemical, power plant, and construction industries and is set by the American Society of Mechanical Engineers (ASME).

3. EN 1092-1 Standard:

This standard is set by the European Standard (EN) and includes technical specifications and dimensions of flanges for use in various industries. Also, the EN standard is considered as one of the most basic technical standards in the flanges industry and is used for connections in piping networks.

5. JIS B2220 Standard:

This standard is set by the Japan Standards Agency (JSA) and is used in the flange industry in Japan and some Asian countries. Finally, the JIS standard also includes the dimensions and specifications of flanges, in the metric system. It should be noted that in addition to these standards, in some industries and countries there are special standards for flanges that are determined based on the local needs and specific conditions of that industry.

Technical Specification Table

Diameter table of flanges according to ASME B16.5 standard

1- Class 150 flanges table

| Nominal Pipe Size NPS (inches) | Class 150 | ||||

|---|---|---|---|---|---|

| Diameter of Flange (inches) | No. of Bolts | Diameter of Bolts (inches) | Diameter of Bolt Holes (inches) | Bolt Circle (inches) | |

| 1/4 | 3-3/8 | 4 | 1/2 | 0.62 | 2-1/4 |

| 1/2 | 3-1/2 | 4 | 1/2 | 0.62 | 2-3/8 |

| 3/4 | 3-7/8 | 4 | 1/2 | 0.62 | 2-3/4 |

| 1 | 4-1/4 | 4 | 1/2 | 0.62 | 3-1/8 |

| 1-1/4 | 4-5/8 | 4 | 1/2 | 0.62 | 3-1/2 |

| 1-1/2 | 5 | 4 | 1/2 | 0.62 | 3-7/8 |

| 2 | 6 | 4 | 5/8 | 0.75 | 4-3/4 |

| 2-1/2 | 7 | 4 | 5/8 | 0.75 | 5-1/2 |

| 3 | 7-1/2 | 4 | 5/8 | 0.75 | 6 |

| 3-1/2 | 8-1/2 | 8 | 5/8 | 0.75 | 7 |

| 4 | 9 | 8 | 5/8 | 0.75 | 7-1/2 |

| 5 | 10 | 8 | 3/4 | 0.88 | 8-1/2 |

| 6 | 11 | 8 | 3/4 | 0.88 | 9-1/2 |

| 8 | 13-1/2 | 8 | 3/4 | 0.88 | 11-3/4 |

| 10 | 16 | 12 | 7/8 | 1 | 14-1/4 |

| 12 | 19 | 12 | 7/8 | 1 | 17 |

| 14 | 21 | 12 | 1 | 1.12 | 18-3/4 |

| 16 | 23-1/2 | 16 | 1 | 1.12 | 21-1/4 |

| 18 | 25 | 16 | 1-1/8 | 1.25 | 22-3/4 |

| 20 | 27-1/2 | 20 | 1-1/8 | 1.25 | 25 |

| 24 | 32 | 20 | 1-1/4 | 1.38 | 29-1/2 |

Table of technical specifications of flanges (all classes) based on the ASME B16.5

Flange Production

AzinForge Company, as its name suggests, uses forging to produce flanges. It uses the closed die forging method to produce flanges from 1/2 to 30 inches and the open die forging method to produce flanges from 30 to 120 inches. It also uses devices such as Counterblow 400kJ hammer, hydraulic press (4000 tons), rolling ring (5 meters), etc. to produce flanges and other products.

Flanges Price

1. Factors influencing the price of flange:

The price of flanges depends on various factors such as the type of raw materials, size and dimensions, standards and their production technology. Also, demand and supply in the market have a great impact on the price of flanges.

2. Flange price determination methods:

1-2. Price of raw materials:

For example, the price of steel, iron, aluminum and other raw materials used in flange production can have a great impact on the final price. Therefore, changes in the market of raw materials can also have a direct effect on the final price of the flange. Also, accurate calculation of material cost and consideration of relevant market variables is essential.

2-2. Cost of production:

Even labor cost, production cost, shipping cost and other costs related to the production of flanges should be considered. Also, the costs of machinery and equipment used in production should also be considered in cost calculations. Therefore, in order to accurately calculate the cost of flange production, all costs related to production, including raw material costs, labor costs, machinery and equipment costs, and other costs, must be considered and collected together to calculate the final cost of flange production.

3-2. Logistics and shipping cost:

For example, the cost of transportation, packaging, insurance and other costs related to the transfer of flanges to the final destination should also be considered in calculating the final price of the product. So, these costs also have a direct impact on the final price and should be carefully considered.

As a result, to accurately determine the price of flanges, the cost of raw materials, production cost and logistics cost should be considered. This price is affected by various factors, including the type of material, dimensions, standard and production technology.

Purchase Flange

To buy a flange, consult and order the product of your choice, please contact our experts in the sales department.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.