Introduction

Socket Weld Flange is a connector that has a protrusion inside the hole. This protrusion is for the pipe to go into the hole and be placed inside it. Then, with the help of welding, a tight and leak-free connection is created between the silent welding flange and the pipe.

Article: What is a flange? | Types | Specifications how to stamping

What is Socket Weld Flange?

Socket Weld Flange (SW) is a connector to pipe, valves and other equipment in piping system and refineries. This flange is suitable for strong and leak-free connections. Therefore, it can be a good alternative to Slip-On Flange or Weld Neck Flange.

Types of face for Socket weld flange

1- Flat Face (FF): It has a smooth and simple inner face and is sealed with a flat gasket.

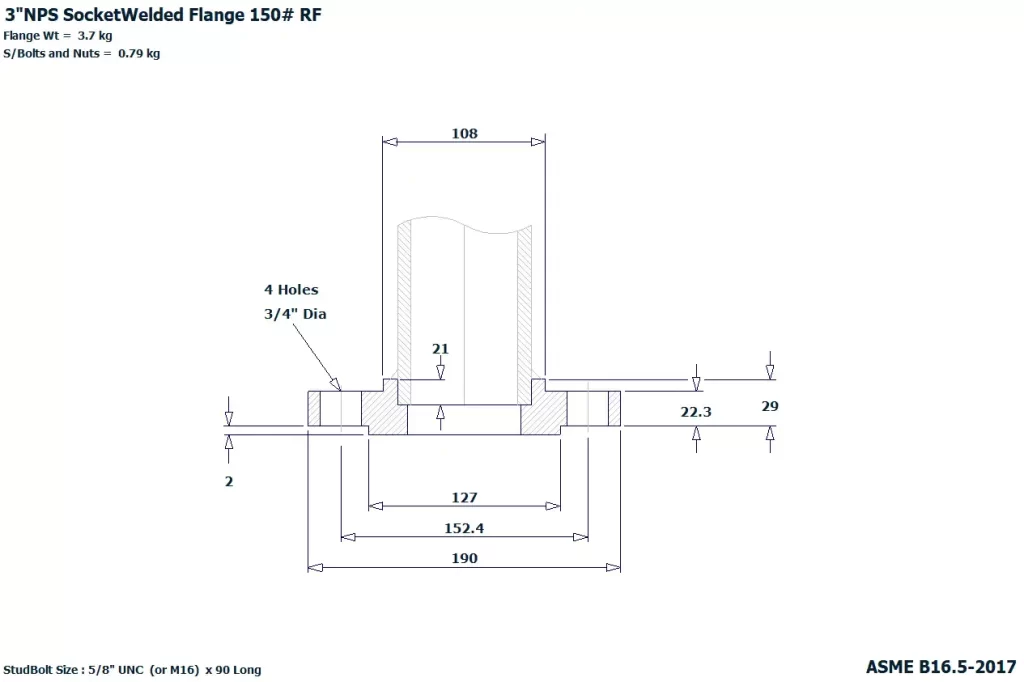

2- Raised Face (RF): This type of face has a protrusion on which a special gasket such as Spiral Wound Gasket is placed in the direction of sealing.

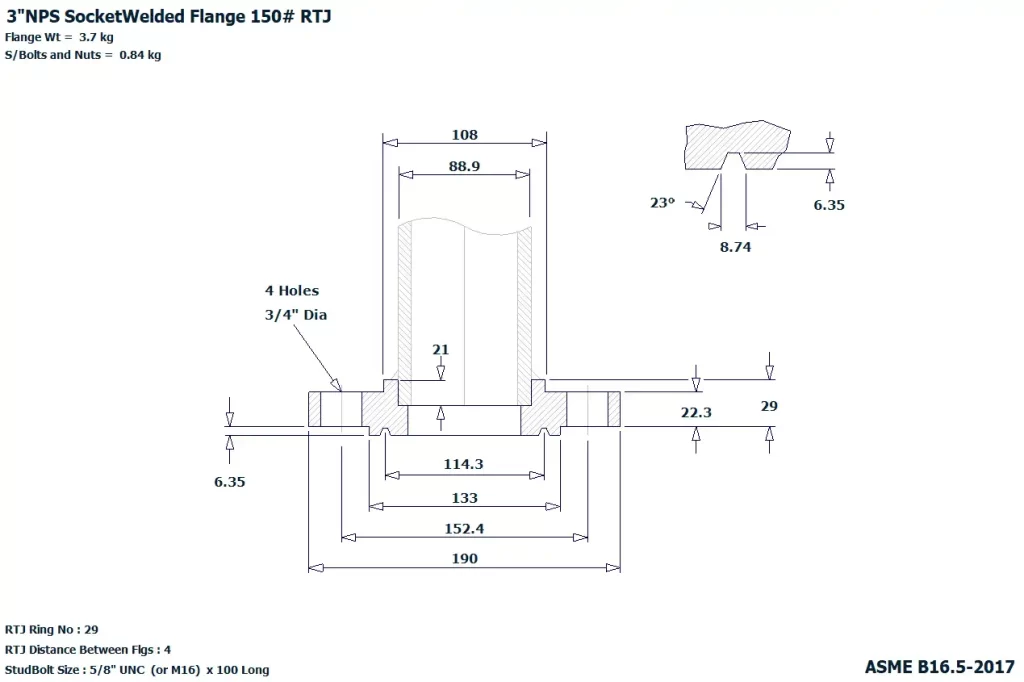

3- Ring Type Joint (RTJ): It has a hollow surface in the form of a ring. Therefore, ring-shaped gaskets, which are usually metal, are used for sealing to create a tight and secure connection.

4- Tongue and Groove (T&G): One flange has an indentation, which is called a groove, and the other flange has a protrusion, which is called a tongue. So, according to this definition, the tongue flange is inserted into the groove flange to create a tight connection.

Each of these types of these face flanges are used for use in different conditions and needs.

Features of Socket Weld Flange

1. Pressure and temperature: This flange can be used in high pressure applications, that is why it is used in industries such as oil, gas and petrochemical.

2. Tight connection: This flange establishes a tight and leak-proof connection with the pipe or other equipment with the help of welding.

3. Different sizes: Socket Weld Flanges are available in different classes and sizes according to the standards. For example, for this flange, there are sizes from 1/2 inch to 24 inches in the ASME B16.5 standard.

4- Class: In the ASME B16.5 standard, the classes for this flange includes: 150, 300, 400, 600, 900, 1500 and 2500.

Some production standards

ASME B16.5 – ASME B16.34 – ASME B36.10 – ASME b36.19 – MSS SP 6 – MSS SP 9 – MSS SP 25 – NACE MR 0175 – ASTM A105 – ASTM A182 – ASTMA350

Contact the sales department (central) in AzinForge for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

The type of raw materials

These types of flanges are usually made of carbon steel, stainless steel or alloy steel to withstand high pressures and temperatures. Also, they are available in different sizes and pressure ratings to replace different types of pipes and operating conditions.

1- Carbon Steel: ASTM A105, ASTM A350/LF2

2- Alloy Steel: ASTM A182, F1, F5, F9, F11, F17, F22

3- Stainless Steel: ASTM A182/F6, F304, F316, F321, F347, F348

Advantages of Socket Weld Flange

1- High resistance: In addition to a strong connection, this method also has high resistance to pressure and heat and has a long service life.

2- Less welding: it does not require a lot of cutting and welding. This reduces time and cost.

3- Size and class: It can be produced in different sizes and classes.

Disadvantages of Socket Weld Flange

1- High cost: using a welding machine to connect the flange to the pipe is expensive. This cost may not be suitable for some projects.

2- The need for special equipment: To use the Socket weld flange, you need a welding machine and relevant technical knowledge.

3- Difficulties in dealing with Pressure: in dealing with a lot of Pressure, it may be difficult to protect its stability. In some cases, frequent repairs may be required.

Conclusion

Before using the socket weld flange, its advantages and disadvantages should be carefully examined and the correct decision should be made according to the specific conditions of the project. These flanges are used in industries such as oil and gas, chemical processing and power generation where high pressure and high temperature applications are common. The use of Socket Weld flange in these industries can improve the efficiency of piping systems. Considering the above disadvantages, before using the silent weld flange, its advantages and disadvantages should be carefully examined and the correct decision should be made according to the specific conditions of the project. For any advice, you can contact the sales department at AzinForge before ordering the desired product.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.