Introduction

Weld Neck (WN) Flange is one of the types of vital flanges in various industries, which are used to connect pipes and equipment to each other in the piping system. This industrial piece has a welded neck that is welded to the pipe and creates a strong and high-strength connection. And due to its special features, it is used as very important and vital connections in oil and gas refineries, chemical industries, petrochemical industries, power plants and marine industries. In this article, we will review the features, applications and importance of weld neck flanges in various industries. Also, we will examine the advantages and limitations of using these types of flanges to check their best use in different industries.

Weld Neck (WN) Flange

Weld Neck Flange is a connector that has a weld neck for pipe or other fittings. Also, due to its structure, this flange is very resistant and stable, and it is suitable for transferring pressure and high temperatures. And it is made of different materials such as carbon steel or stainless steel. For these reasons, the most common type of flange in the market is the weld neck flange.

Features of Weld Neck Flange

One of the important features of the Weld Neck Flange is its strong and stable connection to the pipe or equipment. Because this connector is directly connected to the pipe or equipment using welding. Also, the welding flange has a long neck that allows connection to pipe or equipment. Among the other features of the welded flange are its high resistance to pressure and temperature, structural strength and stability.

The type of raw materials

Pipes and flanges must be durable enough to withstand heat, pressure, vibrations, and corrosion and not leak. Flange class helps determine bore thickness, pressure and temperature ratings, and dimensional standards, but raw material specifications must also be considered based on application:

1- Carbon steel: It is the most common material for flanges and is suitable for applications that require high strength.

2- Stainless steel: used when high durability and corrosion resistance are required.

3- Aluminum: Aluminum flange is used in applications where corrosion resistance and light weight of the material are important.

Choose the right welding flange material based on the intended application and the specific requirements of your project. Generally, the material of your flange will match the material of your pipe, but not always. Also, consider the strengths and weaknesses of each material when designing a plumbing system. This material must comply with project requirements and working conditions, otherwise the component and piping system may fail prematurely.

Contact our specialists in the sales unit for advice, order and purchase of your desired product and inquire about the price.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

AzinForge Company, having the most advanced equipment in the world, including a 5-meter rolling ring, has the ability to produce all kinds of rims and flanges up to 5 meters in diameter. It is worth noting that all flange products produced in AzinForge Company are made by closed die forging, open die Forging and ring rolling method.

Weld Neck Flange Standard

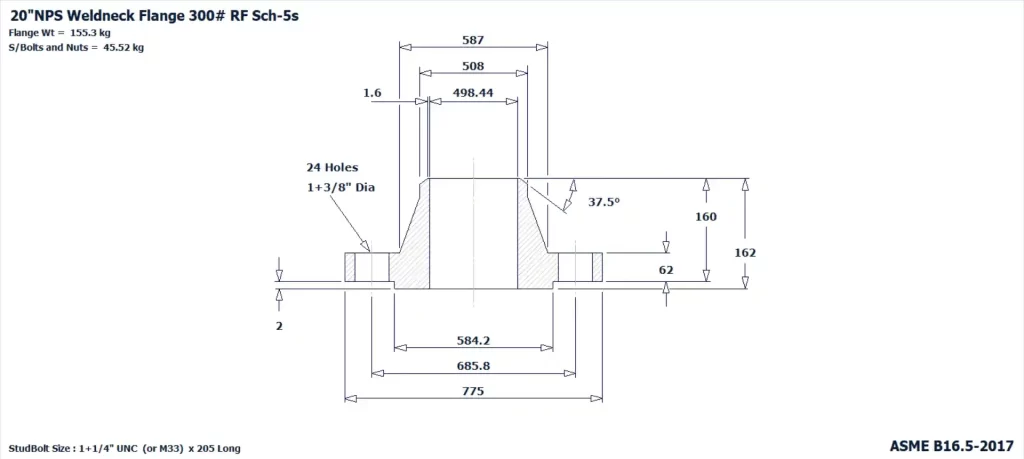

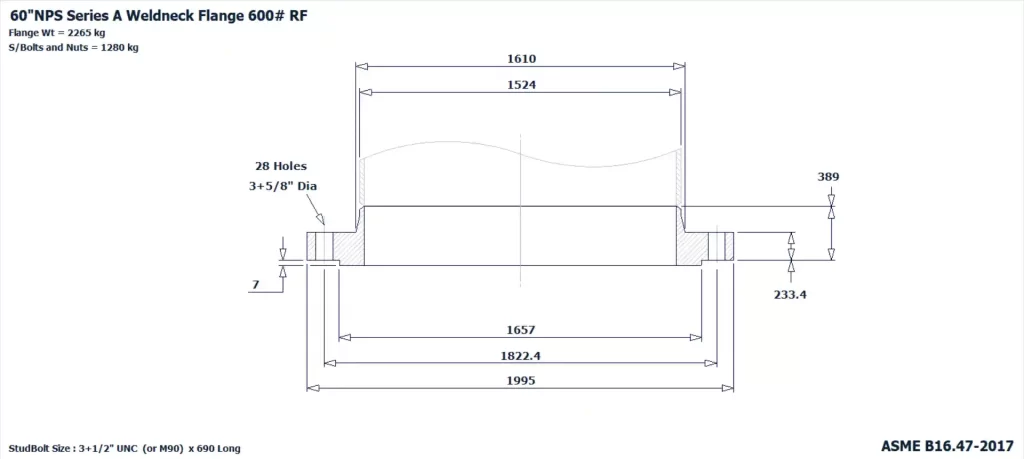

In general, the welded throat flange is used to connect the pipes in the piping system. Due to their geometric shape, it is very easy to identify them. In picture number 3 and 4, you can see the schematic map for this flange. Therefore, in these schematics, the dimensions, internal hole diameter, thickness, length, number of screw holes and also the final weight are determined according to ASME standards (AzinForge also produces non-standard flanges according to customer requests).

As you can see in picture number 3, this 20-inch weld neck flange product is in work class 300 according to ASME B16.5 standard and all diameters and sizes are specified according to the standard. And in the ASME standard, the largest flange, according to the ASME B16.47 Serie A standard, is in work class 600, which has a diameter of 60 inches and a weight of 2265 kg.

Advantages of Weld Neck Flange

1. High Strength: Weld Neck Flanges have high strength and tight connection, which are suitable for use in high pressure and high temperature systems.

2. Stability: These types of flanges have high stability against pressure and temperature and can work well in difficult conditions.

3. Corrosion Resistance: According to the standard and the type of raw materials (for example, ASTM A182), weld neck flanges can have high resistance in chemical corrosive environments.

4. Proportionate Structure: The special structure of weld neck flanges makes them have strong and stable connections and are also attractive in appearance.

Disadvantages of Weld Neck Flange

1. High cost: The production and installation of weld neck flanges has a high cost, which may be a limitation for some projects.

2. The need for special skills and equipment: installing and welding throat flanges requires special equipment and skills, which may create challenges for some applications.

3. High weight: Weld neck flanges usually have high weight (in large size), which may be problematic to install and transport.

Limitations on repairs: If repair is needed, removing and rewelding this type of flange can be time-consuming and complicated.

Conclusion

Considering the advantages and disadvantages of throat welding flanges, we can conclude that these types of flanges are suitable for use in high pressure conditions, high temperatures and corrosive environments.

But their high cost, the need for special skills and equipment, and their high weight may limit their use in some applications.

Therefore, before using weld neck flanges, it is necessary to check their advantages and disadvantages carefully and ensure the ability and suitable conditions for their use.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.