Introduction

Slip On Flange is an industrial piece for connecting pipes in piping systems. In the continuation of this article, we mention the features of this flange, its application, the type of raw materials, existing standards, and an example of the specification table in the ASME B16.5 standard.

What is Slip On Flange?

Slip On (SO) Flange is one of the types of flanges used to connect pipes, valves and pumps in the piping system for refineries and power plants, etc. This flange has a variety of face flange types such as Raised Face (RF), Flat Face (FF) and Ring Type Joint (RTJ), and it is easily welded to the pipe and using bolts is connected to another pipe. Also, due to the simplicity of the structure and installation, this flange is less expensive than other types of flanges and is suitable for connections with lower pressure. In industrial piping systems, these parts are used for quick and easy connection and disconnection.

Article: What is a flange? | Types | Specifications how to stamping

Type of Slip On Flanges based on the face

1. Flat Face Flange (FF): It has a smooth and simple face and to seal it, they use flat gaskets that are placed on the entire disk.

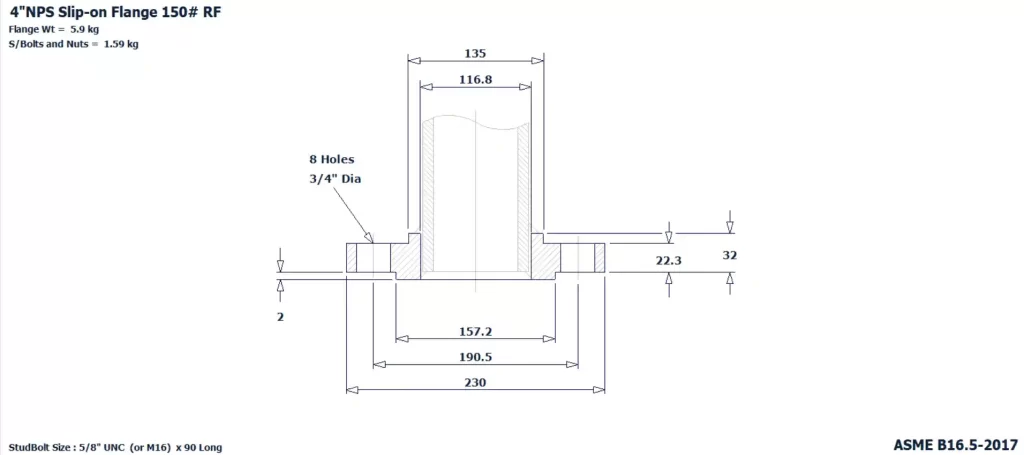

2. Raised Face Flange (RF): It has a raised inner face that is connected to the flange of the same shape with the help of a special gasket like serrated. So, this joint is tightly sealed with gaskets to prevent leakage.

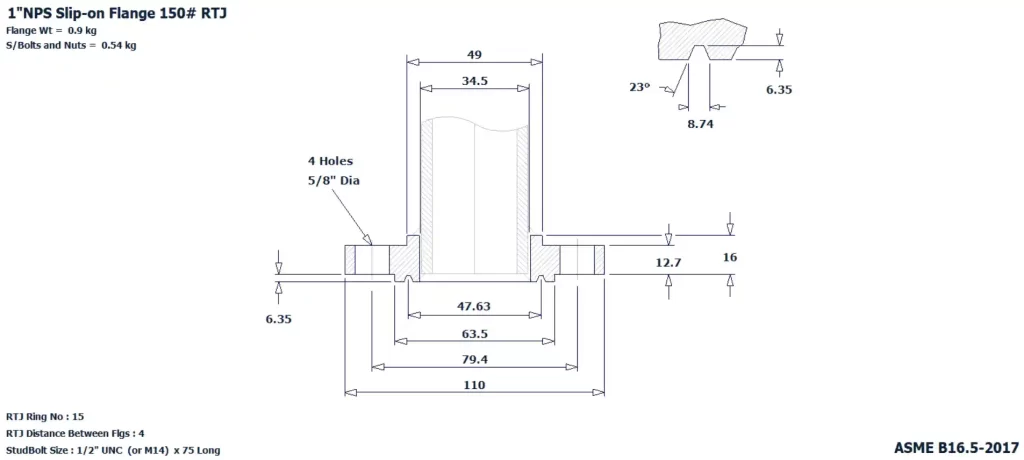

3. Ring Type Joint Flange (RTJ): The face of this type of flange has a ring-like indentation that uses a ring gasket that is usually metal. For this reason, it is more suitable for higher pressure and temperature than Slip-On flange.

Slip On Flange features

1. Easy installation: Due to its special design, the Slip On Flange is easy to install and does not require much welding.

2. Quick disassembly: Due to not needing many bolts and nuts, the disassembly of Slip On Flange is very simple and fast.

3. Lower cost: Due to the simplicity of the structure and installation, the Slip-On Flange has a lower cost than other types of flanges.

4. Suitable for low pressure: Slip-On Flange is not suitable for high pressure applications because the protruding hub may not withstand the high pressure.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

5. Weight: According to the ASME B16.5 standard, the weight of the Slip On Flange reaches 0.8 kg according to the size 1/2 and working class 150, and it reaches 608 kg in the size of 24 inches class 900.

6. Weight of bolts and nuts: In the size of 1/2 inch and class 150, the weight of bolts and nuts is approximately 0.46 kg. Also, in the size of 24 inches, class 900, the weight of bolts and nuts reaches approximately 345 kg.

Application of Slip On Flange

As we mentioned before, this flange is a type of flange that is used for connection in piping system and refineries, etc. So, this type of flange is usually used to connect pipes to equipment such as valves, pumps and tanks. Also, some of the industries that use it are:

1. Water cooling lines

2. Fire lines

3. Low pressure compressed air lines

4. Process lines for materials such as steam

5. Oil and gas lines

The type of raw materials

Slip On Flanges are made of different types of materials, especially based on environmental requirements and application conditions. And some common ingredients include:

1. Carbon Steel:

This is one of the most common materials for making Slip On Flanges. Also, carbon steel is suitable for many applications due to its high resistance to pressure and heat, affordability and formability.

2. Stainless Steel:

For environments exposed to moisture, acids or other environmental conditions, Slip On Flanges are made of stainless steel (304 or 316).

3. Alloy Steel:

For special conditions such as high temperature or high corrosion resistance, Slip On Flanges are made of special alloys such as aluminum, titanium or nickel steel.

4. Plastic: For some applications such as chemical or water and sewage industries, Slip On Flanges are made of plastic materials such as PVC or CPVC.

Each of these materials has its own characteristics and advantages and should be selected according to the application conditions and relevant standards.

Standard Slip On Flange

Slip On Flange is made according to different standards. So, some of the most famous Slip On Flange standards are:

1. ASME Standard:

This standard specifies specifications for Slip On Flanges of various sizes and pressures. For example, ASME B16.5 and ASME 15.36 are used for these flanges with different dimensions and pressures.

2. EN Standard:

EN 1092-1 standard is used for European flanges with specified dimensions and pressures. So, this standard specifies specifications for Slip On Flanges with metric dimensions and PN (Nominal Pressure) pressures.

Contact the sales department (central) in AzinForge for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

3. JIS Standard:

JIS B2220 standard is used for Japanese standard flanges with specified dimensions and pressures.

4. MSS SP Standard:

The MSS SP-44 standard also determines specifications for Slip On flanges with specific dimensions and pressures.

These standards determine specifications including dimensions, pressures, construction materials, test methods and other specifications of Slip On Flanges.

AzinForge company has created jobs for 800 people and indirectly for 2000 people in upstream and downstream industries and also has the ability to produce any type of rim and flange up to 5 meters in diameter.

Specification table

Below is a table of Slip On Flange specifications based on ASME B16.5. These specifications include dimensions, pressures, construction materials, test methods and other technical specifications related to SLIP ON flange.

| Dimensions | Classes | Materials | Test methods |

|---|---|---|---|

| 1/2″ to 24″ inch | 150، 300، 600، 900، 1500، 2500 | Carbon steel, stainless steel, special alloys | Hydrostatic test, non-destructive test |

Conclusion

As a result, Slip On Flange is widely used in various industries due to its easy installation and connection. but also, these flanges are usually used for connections that require frequent changes or in environments that require easy access to connections. In general, Slip On Flanges are a quick and effective solution for connecting pipes and various equipment. AzinForge Company is the largest and best manufacturer of open forge and closed forge flanges in the country.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.