Introduction

A flange is a connector for pipes, pumps in the industrial piping system, and one of the most famous of them is the Ring Type Joint Flange, which is used in various industries, including oil and gas. In the rest of this article, we will discuss the characteristics, application, type of raw materials and its production standards.

What is Ring Type Joint (RTJ) Flange?

Ring Type Joint Flange (RTJ) is a vital part in pipe connections in the piping system, by which we can create a tight and leak-free connection. On the face of the inner disk of this type of flange, there is an indentation for the placement of a metal or graphite ring gasket, which creates a tight and leak-free connection.

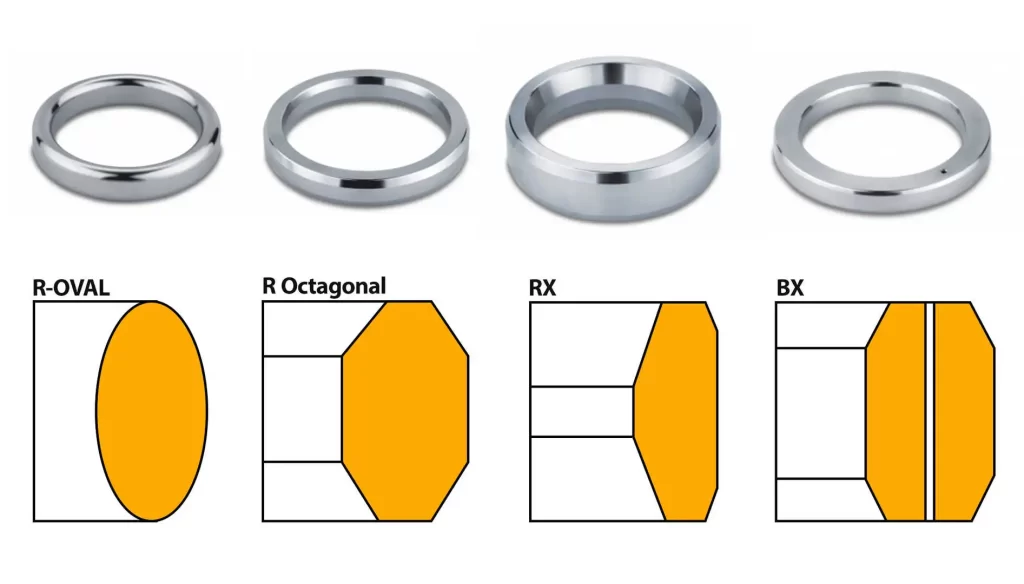

Types of Ring Joint Gasket

The types of ring joint gaskets are:

R-OVAL | R Octagonal | RX | BX

Ring Type Joint Flange Structure

The type of raw materials

These types of flanges are usually made of carbon steel, stainless steel or alloy steel to withstand high pressures and temperatures. They are available in different sizes and pressure ratings to replace different types of pipes and operating conditions.

1. Carbon Steel: ASTM A105, ASTM A350/LF2

2. Alloy Steel: ASTM A182, F1, F5, F9, F11, F17, F22

3. Stainless Steel: ASTM A182/F6, F304, F316, F321, F347, F348

Gasket (Ring Joint)

The material of these pieces can be mild steel, low carbon steel, alloy steel (such as F5 and 410), stainless steel (304, 304L, 316, 316L, 321, 347, 410), nickel and titanium alloys.

Bolts and Nuts

Bolts and nuts are used to tighten the connection between two flange ring joints and seal between them.

Some production standards in AzinForge

ASME B16.5 – ASME B16.34 – ASME B36.10 – ASME b36.19 – MSS SP 6 – MSS SP 9 – MSS SP 25 – NACE MR 0175 – ASTM A105 – ASTM A182 – ASTMA350

Contact the sales department (central) in AzinForge for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Advantages and Disadvantages

Advantages:

1. Pressure: ring type joint flange is suitable for high-pressure connections and also, can withstand lateral forces.

2. Temperature: This type of flange is able to withstand very high-temperatures (up to 1000°F) and is also suitable for use at low-temperatures.

3. Strong connection: Ring type joint flange is able to create a strong and seamless connection between the flange and the pipe due to the use of the ring joint gasket.

4. Dangerous environments: this type of flange is suitable for use in environments that are in contact with dangerous substances, poisons or flammable substances.

Disadvantages:

1. Cost: Ring type joint flange (RTJ) has a high cost and is usually an expensive option.

2. Complexity of installation: Installation and disassembly of ring type joint flange requires skill and experience and may be time-consuming and complicated.

3. Need for ring joint gasket: To use flange ring joint gasket, you need a suitable ring joint ring and you must ensure the quality and correct selection of ring joint ring.

However, considering the available advantages and disadvantages, please consult with our experts at the sales department before purchasing the flange you want.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.