Introduction

In this article, we want to talk about the Tongue and Groove (T&G) flange, its types, features, application and standards, as well as the difference between the T&G flange and Ring Type Joint (RTJ) flange, and you can also see more articles on the blog, Azin Forge website.

What is a Tongue and Groove Flange?

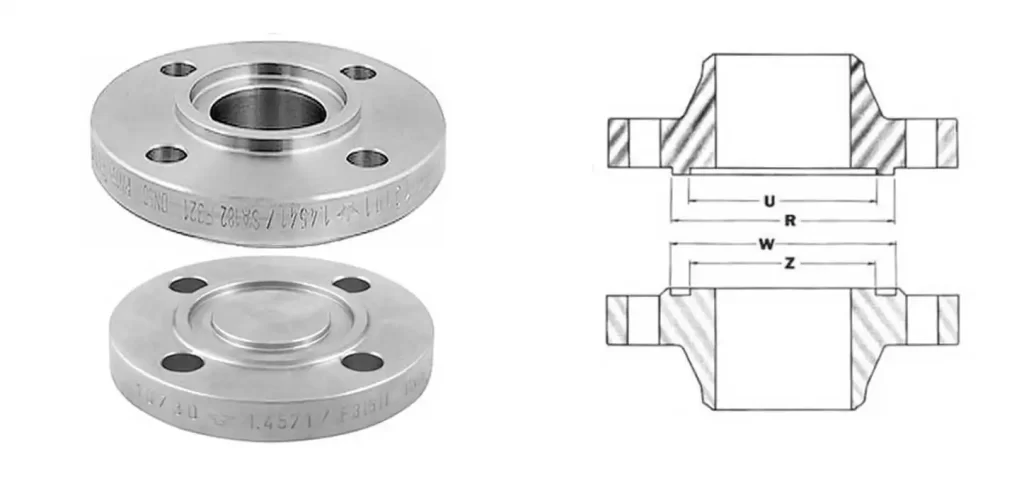

A tongue & Groove (T&G) flange is a type of flange that is used to connect pipes and piping parts together. So, its has a special design that enables a correct and tight connection between parts.

T&G flange design

As you know, T&G flange has two parts. The tongue part is a projection that is directly on one side and the groove part is a recess that is placed on the opposite side of the flange. The tongue and groove lock tightly together, creating a strong and seamless connection between the parts. You can also read the Flat Face (FF) Flanges article.

Types of Tongue and Groove flanges

Specification of raw materials (AzinForge)

The following specifications are listed based on the ASME B16.5 standard.

1. Stainless steel

ASTM A 182, A 240 F 304, 304L, 304H, 316, 316L, 316Ti, 310, 310S, 321, 321H, 317, 347, 347H, 904L

2. Carbon steel

ASTM / ASME A/SA 105 ASTM / ASME A 350, ASTM A 181 LF 2 / A516 Gr.70 A36, A694 F42, F46, F52, F60, F65, F706

3. Carbon steel (for low temperature)

ASTM A350, LF2, LF3

4. Double layer steel

ASTM / ASME A/SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61

Contact AzinFoge specialists in the sales unit for advice, order and purchase of your desired product and inquire about the price.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

5. Alloy steel

ASTM / ASME A/SA 182 & A 387 F1, F5, F9, F11, F12, F22, F91

6. Copper alloy steel

ASTM SB 61, SB62, SB151, SB152 UNS No. C 70600 (Cu-Ni 90/10), C 71500 (Cu-Ni 70/30), UNS No. C 10100, 10200, 10300, 10800, 12000, 12200

7. Nickel alloy steel

ASTM SB564, SB160, SB472, SB162 Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201), Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020)

Features of Tongue & Groove (T&G) flange

1. Strong connection and strength: T&G flange provides a strong connection between flange parts by using suitable bolts and nuts. It provides a strong connection and high strength and prevents leakage and moisture in the joints.

2. Preventing leakage: T&G flange has the ability to prevent leakage in connections by properly adjusting the bolts and nuts and using the right materials. This important feature is very important in many industries including oil and gas and chemical.

3. Easy to replace and repair: T&G flange is easy to replace and repair. By opening the bolts and nuts, it is possible to replace the defective parts or repair them. This feature reduces maintenance costs.

4. Ability to withstand high pressure and temperature: T&G flange is able to withstand high pressure and temperature due to the class and type of raw materials. This feature makes it suitable for use in industries such as oil and gas refineries, power plants.

5. Resistance to corrosion and other damage: T&G flange is usually made of steel or aluminum, which has high resistance to corrosion and other damage. This feature makes it suitable for use in harsh environments and harsh conditions.

Due to these features, T&G flange is used as a strong and reliable connection in various industries and is considered.

Application of T&G flange

1- Oil and gas industries: These flanges are used to connect gas, oil and other chemical pipes that require high resistance to pressure and temperature.

2- Chemical industries: T&G flanges are used in chemical industries to connect pipes and various equipment.

3- Water and sewage industries: T&G flanges are used to connect water and sewage pipes and related equipment.

1- Oil and gas industries: these flanges are used to connect gas, oil and other chemical pipes that require high resistance to pressure and temperature.

2- Chemical industries: T&G flanges are used in chemical industries to connect pipes and various equipment.

3- Water and sewage industries: T&G flanges are used to connect water and sewage pipes and related equipment.

Tongue and Groove (T&G) Flange Standards

Manufacturing standards can vary depending on different applications and locations. But in general, the standards that exist for the manufacture of T&G flanges are:

1- ANSI/ASME B16.5 standard: This standard is used for steel flanges with dimensions NPS 1/2 to NPS 24 and working pressure class 150 to class 2500.

2- DIN EN 1092-1 standard: This standard is used for steel and aluminum flanges with dimensions DN 10 to DN 4000 and working pressure PN 2.5 to PN 400.

3- JIS B2220 standard: This standard is used for steel flanges with dimensions from 10A to 1500A and working pressure from 5K to 63K.

4- BS 4504 standard: This standard is used for steel flanges with dimensions DN 10 to DN 4000 and working pressure PN 2.5 to PN 400.

5- AS 2129 standard: This standard is used for steel flanges with dimensions 10A to 600A and working pressure PN 2.5 to PN 40.

6- MSS SP-44 standard: This standard is used for steel flanges with dimensions NPS 12 to NPS 60 and working pressure class 150 to class 2500.

7- ISO 7005-1 standard: This standard is used for steel flanges with dimensions DN 10 to DN 4000 and working pressure PN 2.5 to PN 400.

These standards are used to guarantee the quality and compatibility of T&G flanges with various systems and equipment.

Difference between T&G and RTJ flange

T&G flange and RTJ flange are two different types of flanges that are used in connecting pipes and industrial equipment. The main differences between these two types of flanges are:

1- Design and connection system:

T&G flange has two different flanges. One side has a tongue and the other side has a groove where the tongue flange enters the groove flange. While the RTJ flange has an indentation that is sealed and secured with the help of special ring gaskets.

2- Use in pressure and temperature:

T&G flange is generally used for lower pressure and temperature, while RTJ flange is suitable for higher pressure and temperature. This difference is due to different design and construction materials.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.