Introduction

Flanges are one of the basic components in piping systems and industrial connections that are used to connect and transfer fluids and gases. One of their common types is the raised face flange, which is used as one of the standard fittings to connect pipes, valves and other equipment together. In the continuation of this article, we will review the technical specifications, applications and standards related to raised face flange (RF).

What is Raised Face Flange (RF)?

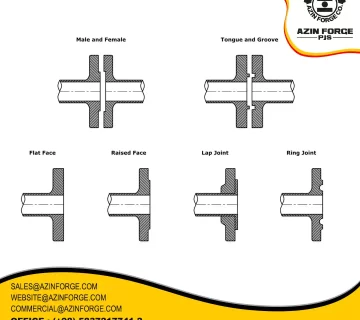

Raised Face Flange (RF) is a type of connector used to connect pipes, valves or other equipment. The word RF means Raised Face and therefore it is also known as this name in the piping system. In fact, the inner surface of each flange can be Raised Face (RF), Ring Type Joint (RTJ) or Flat Face (FF).

These flanges are used for connections that require a strong and reliable connection and through which fluids or gases with high pressure and temperature are transferred. This industrial piece is used as one of the standard connections in oil and gas stations, petrochemical industries, water and sewage.

Types of Raised Face Flanges

There are many types of flanges with Raised Face, some of them are:

2. Blind Flange

Each of these types of flanges have specific specifications and applications and are used in different industrial conditions.

The type of raw materials

Raised Face (RF) flanges are usually made of different materials, which can be different depending on the working conditions and the needs of the selection of construction materials. Some common materials for making RF flanges include:

1. Carbon steel: One of the common materials for making flanges is carbon steel, which is suitable for use in medium pressure and temperature conditions.

2. Stainless steel: For conditions that require high-resistance to corrosion and high-temperatures, flanges are made of stainless steel.

3. Aluminum: Some flanges are made of aluminum, which are suitable for applications that require light weight and corrosion resistance.

These are just a few examples of materials used to make RF flanges and depending on the specific application conditions, other materials may also be used to make these flanges.

Technical specifications of Raised Face flange

Raised Face flanges have special technical specifications that we must consider for their correct selection and use. These specifications include diameter (pipe size), pressure, temperature, protrusion size, edge size and type of material. For example, the RF flange is suitable for use in high-pressure and medium-temperature conditions.

Of course, below is an example of a specification table for an RF flange:

| diameter (pipe size) | Pressure (psi) | Temperature (degrees Fahrenheit) | Protrusion Size (inches) | edge Size (inches) | materials |

|---|---|---|---|---|---|

| 1/2″ | 150 | 500 | 1/16″ | 1/4″ | Carbon steel |

| 3/4″ | 300 | 600 | 3/32″ | 5/16″ | Stainless steel |

| 1″ | 600 | 700 | 1/8″ | 3/8″ | Aluminum |

| 2″ | 900 | 800 | 5/32″ | 7/16″ | Stainless steel |

This table is part of the technical specifications for the RF flange, and there are many other types that have different specifications.

Contact the sales department (central) in AzinForge for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Application of Raised Face flange

Raised Face flanges are used in various industries such as oil and gas, petrochemical, water and sewage industries. These flanges are used to connect and transfer fluids and gases safely and reliably.

Related standards

Raised Face flange manufacturing standards include ANSI/ASME, DIN, and JIS standards. Each of these standards has its own technical specifications and is used for different types of flanges. For example, the ASME B16.5 standard is used for steel flanges in the United States and the DIN 2576 standard for stainless steel flanges in Europe.

Conclusion

Raised Face flange is one of the important types of flanges in various industries, which is used for connecting pipes and industrial equipment. Technical specifications, applications and standards related to this type of flange should be carefully examined to ensure its correct selection and use. For this reason, before taking any action, you can contact AzinForge and get the necessary advice to buy the part you want.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.