What is a Forging?

Forge means blacksmithing, and forging in the industry means pressing and hammering metal ingots. Using hammer and anvil is one of the oldest forging methods. At first, the metal is heated and then by holding it on the anvil, with the help of pliers, they shape it with a hammer. Be with us so that in the rest of this article we will examine the forging process, the types of forge methods and the difference between forging and casting.

Last update: 06/30/2024 | Approximate study time: 13 min

- 1 What is a Forging?

- 2 Forging process steps

- 3 Types of forging based on temperature

- 4 Types of forge based on temperature

- 5 Types of forge methods

- 6 High Energy Rate Forging

- 7 Coining

- 8 The types of raw material for forge

- 9 The difference between forging and casting

- 10 Advantages

- 11 Disadvantages

- 12 Final word

Forging process steps

1. Mold design and creation: This step is not required for closed mold steel forge parts.

2. Cutting and heating: In this step, the metal billet is cut and heated by heat treatment furnaces.

3. Forging operation (shaping): After the metal ingot is heated, it is turned into the desired shape by hammering and compression, however, some material around the produced product, called flash, remains, which must be cleaned.

4. Trimming: The process of removing waste materials (police and flash) from the formed metal is called cleaning.

5. Heat Treatment: In this step, the desired metal is heated without changing its appearance and then cooled, because the strength, corrosion resistance and machinability are increased. However, this step is executed when needed.

6. Shot Blasting: A technology in which small particles (metal, sand and gravel) hit the surface of the forged product at high speed to clean it.

7. Machining: CNC machining is used to achieve precise size and chipping.

8. Surface Treatment: The operations performed on the surface of the product to increase resistance to corrosion, decay, etc., are called surface treatment. At this stage, operations such as painting, polishing the product and using artificial glossy coatings are performed.

9. Inspection and quality control: inspection and quality control of the forged products produced by experts in the quality control unit.

10. Packaging and delivery: Finally, the final products are packed in AzinForge and sent to the valuable customers of this company.

Forge means blacksmithing, and forging in the industry means pressing and hammering metal ingots. Using hammer and anvil is one of the oldest forging methods. At first, the metal is heated and then by holding it on the anvil, with the help of pliers, they shape it with a hammer. Be with us so that in the rest of this article we will examine the forging process, the types of forge methods and the difference between forging and casting.

Types of forging based on temperature

Cold Forging

The cold forge process is carried out close to room temperature. It is usually done under a temperature of 300 degrees Celsius.

Warm forging

As an alternative process to the cold process and of course it can be combined with it. Initially, the metal ingot is heated at an average temperature between 700 and 950 degrees Celsius and is usually used for materials such as alloy steel that cool later.

Hot forging

In this process, metals are shaped at a higher temperature (between 950 and 1250 degrees Celsius).

Isothermal Forging

The isothermal forge process is an advanced type of hot forging. First, the desired mold is brought to the temperature of the metal and then this temperature is maintained until the end of the forging operation.

Types of forge based on temperature

Normal Forging

It is a production process in which metals are shaped by hammering, compression and rolling, and then the metal is shaped and machined to become the final design.

Precision Forging

An innovative process to produce high-performance parts that are flash-free and nearly pure. Therefore, it requires less machining and sometimes it doesn’t need it.

Types of forge methods

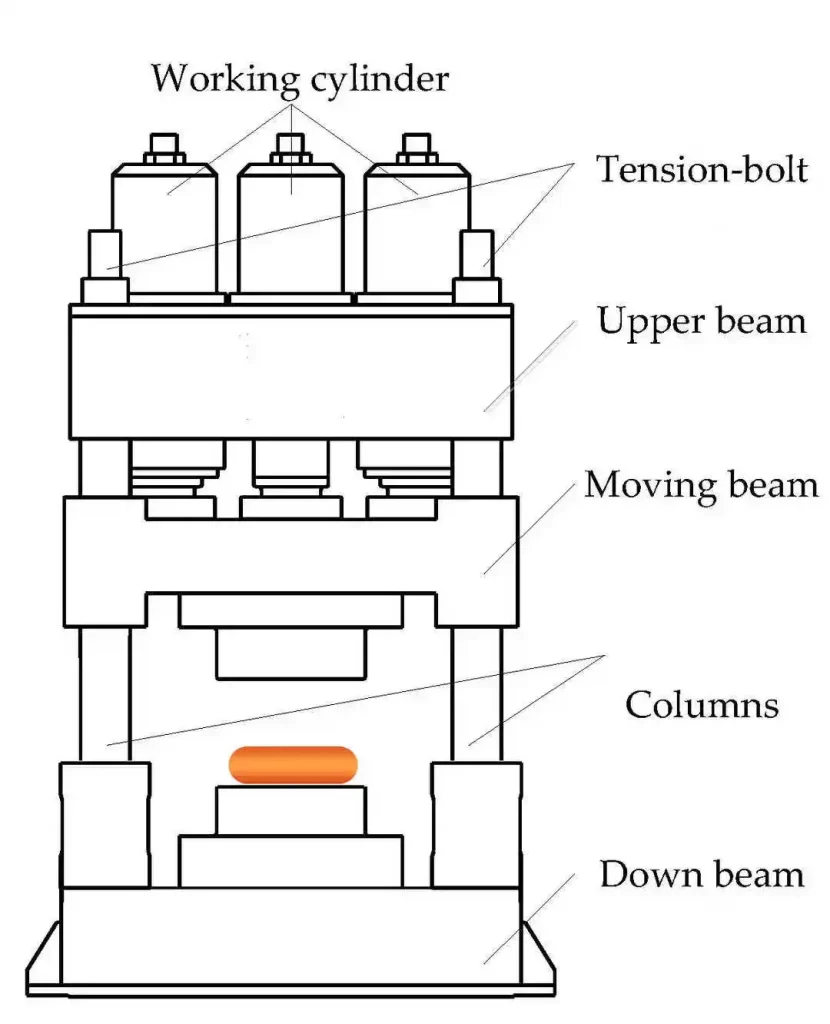

Press Forging

A method of turning a metal into the desired shape by applying gradual pressure is called forging press. AzinForge uses a device such as a hydraulic press (4000 tons) to perform this operation.

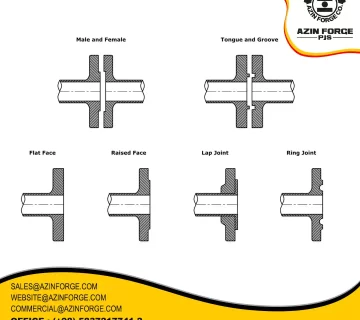

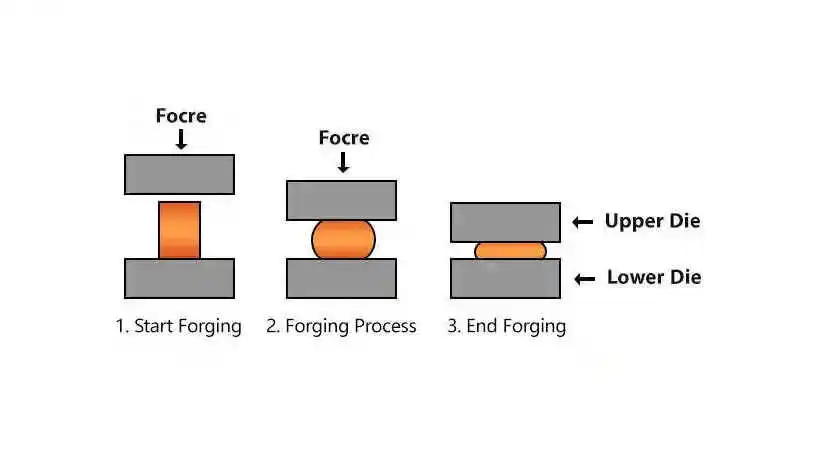

Open Die Forging

It is a shaping method in which the mold does not contain the metal and it is shaped by hammering, which is usually in the form of upsetting.

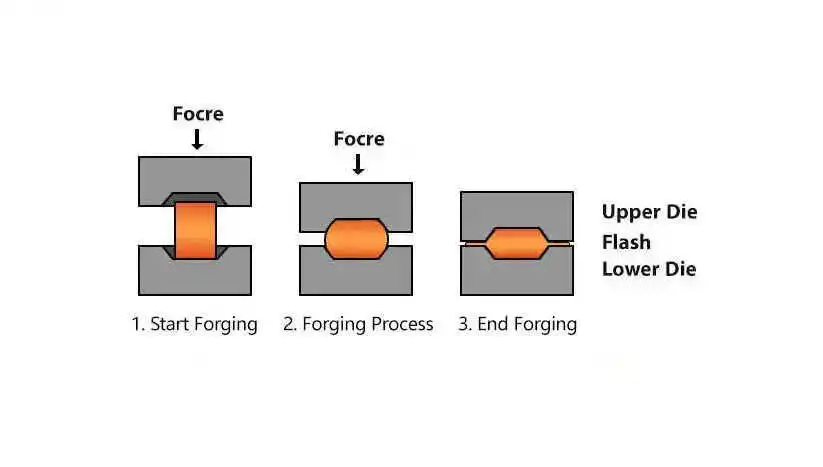

Impression Die Forging

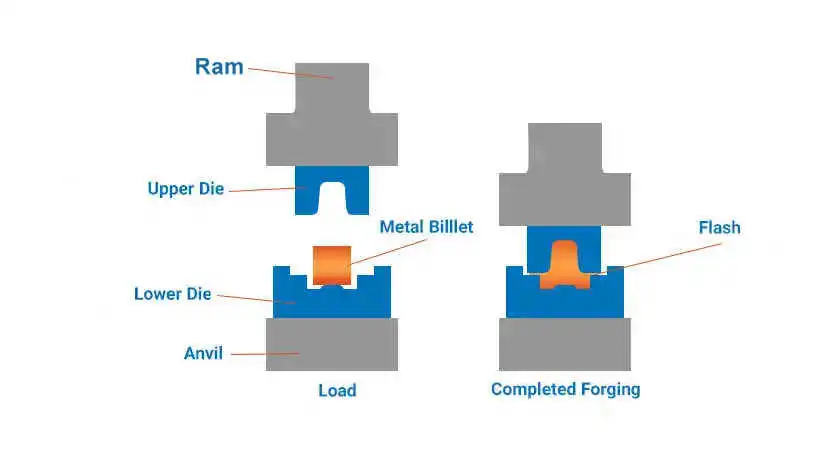

In this method, the metal ingot is placed in a fixed mold. Then, another movable mold descends on the metal ingot and makes the metal into the final shape by hammering and sledgehammering.

Flashless Forging

Flash forging is a new method for producing metal parts. In this method, the forging process is done as Impression. Its advantages include reducing flash and shortening product production time.

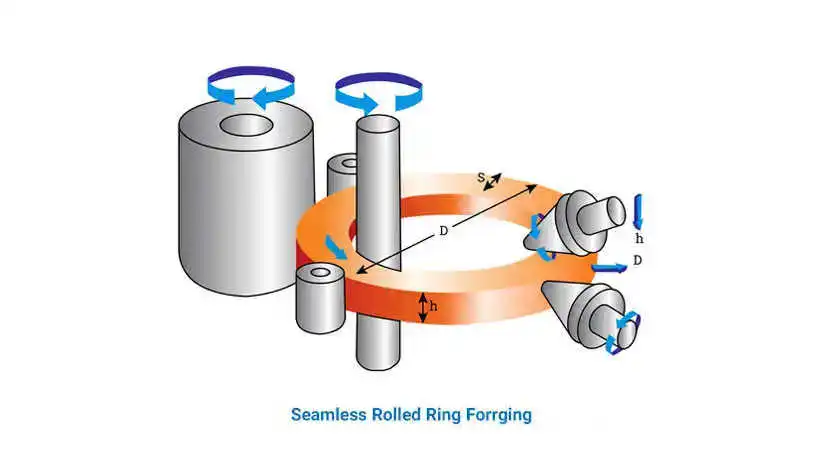

Seamless Rolled Ring Forging

To produce seamless rims, rolling ring machines are usually used, which are available in different sizes. Also, AzinForge is equipped with a 5-meter ring rolling machine to produce its rings and flanges.

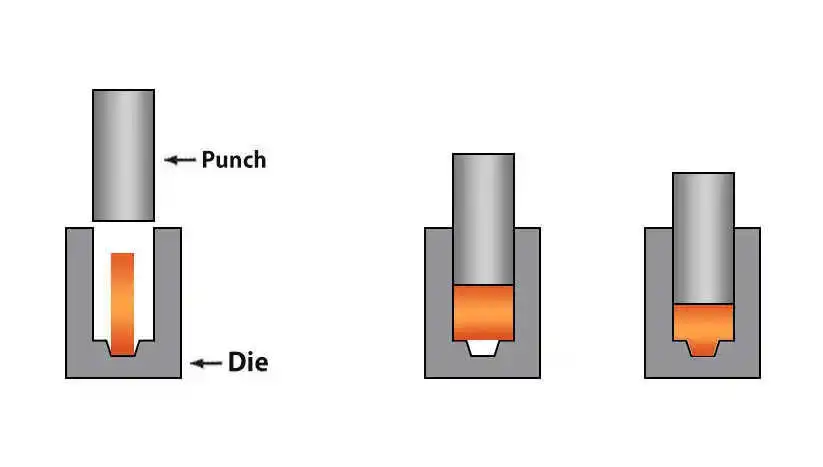

Drop Forging

In this method, the metal ingot is placed in a mold. The upper mold is then dropped onto the metal billet to produce the final shape. After this operation, the waste material is easily separated from the final product.

Upsetting Forging

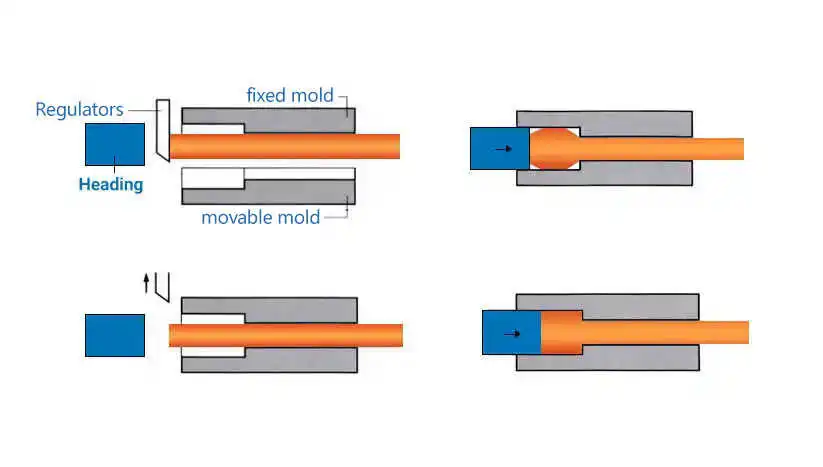

It is one of the types of forge methods to produce quality products. In this method, first the metal ingot is placed between two molds. Then, with the help of the pressure force produced by the heading tool, it becomes the final shape. This method is implemented horizontally or vertically to enlarge and change the shape of the end surface of the bar or uniform metals.

Upsetting Forging

It is one of the types of forge methods to produce quality products. In this method, first the metal ingot is placed between two molds. Then, with the help of the pressure force produced by the heading tool, it becomes the final shape. This method is implemented horizontally or vertically to enlarge and change the shape of the end surface of the bar or uniform metals.

Contact our specialists in the sales unit for advice, order and purchase of your desired product and inquire about the price.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Roll Forging

Roll forging is a process in which a metal ingot is heated and then placed between two rolls that have a specific shape. Finally, by turning two molds on the metal, they turn it into the desired shape.

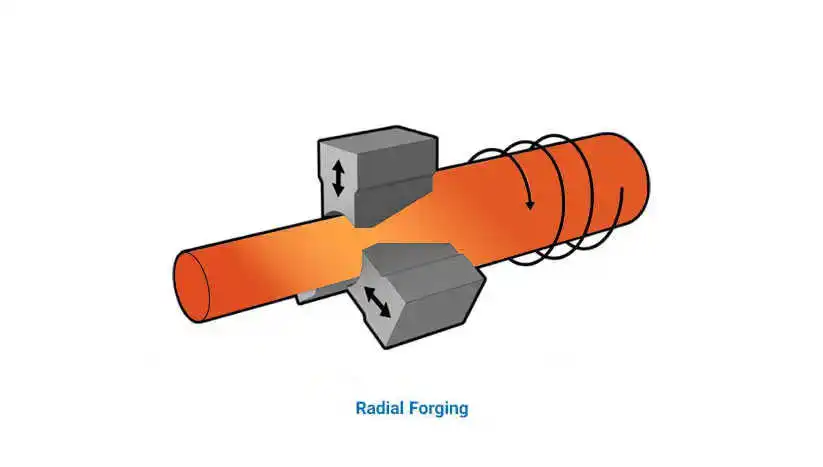

Radial Forging

One of the types of forge methods that can be done using a special device. The desired metal ingot is received by a lever called Manipulator. Then, with the help of this lever, the metal ingot rotates in its own axis and enters the press machine.

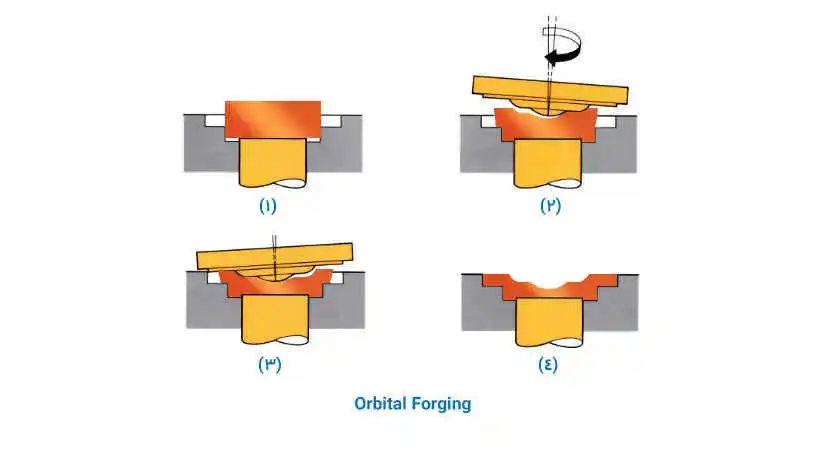

Orbital Forging

Orbital forging is one of the types of forge methods in which the metal ingot is placed in the forging mold and then it is turned into the desired shape by the upper mold by applying pressure in a rotational manner.

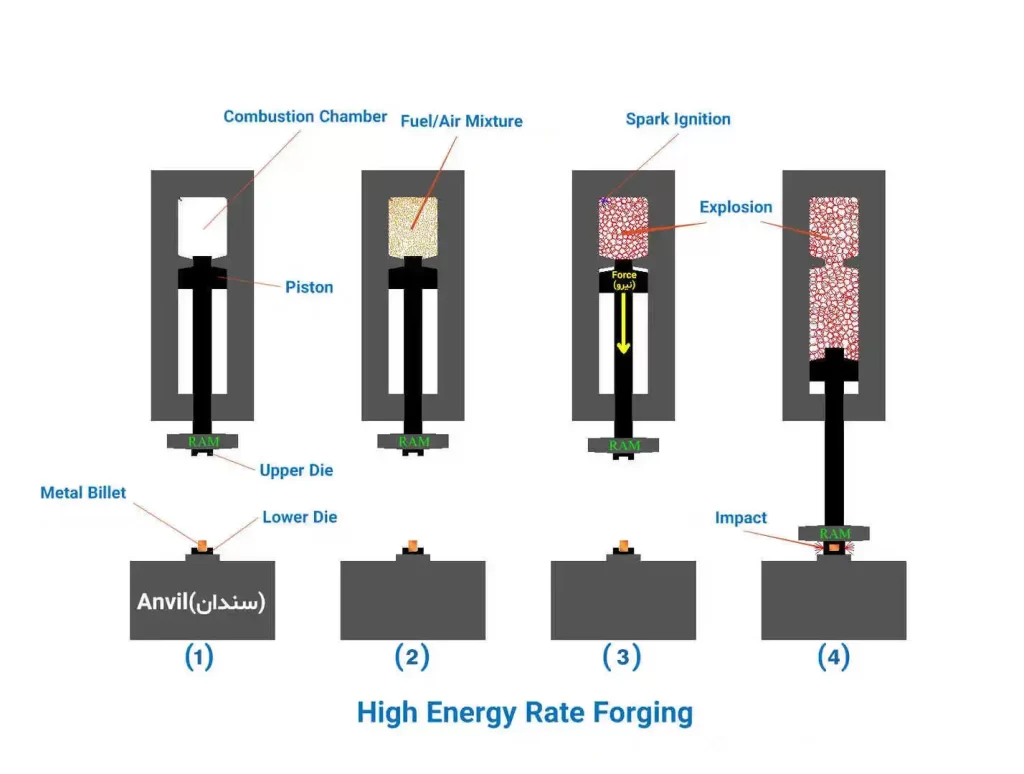

High Energy Rate Forging

A forge process that happens in a few thousandths of a second. For this reason, this process is very useful for the production of hard metals.

Powder Metal Forging

It is a combination of powder and forge, that is why it is called powder forging. In this method, powder is used because it increases formability and minimizes scrap waste. They also use this method to make aerospace and automotive equipment, biomedical devices, brake pads, marine equipment, spacecraft heat shields.

Coining

It is one of the types of forge methods, which is done in the form of an impression mold. Therefore, the entire surface of the metal cut is etched to leave a precise impression of the mold on the metal. Because they use this method to produce coins, medals and jewelry.

The types of raw material for forge

Carbon, stainless and alloy steel

aluminum

Titanium

copper

Rice

Alloys such as nickel, molybdenum, cobalt and…

The difference between forging and casting

In forging, the metal ingot is transformed into the desired shape by hammering and pressure. For this reason, the resistance in this method is higher than the casting method. It also reduces the defects and voids in the metal to zero. Whereas, in casting, the metal is completely melted first. Then these molten materials are introduced into the mold and after the materials cool down, the desired product is created. For this reason, the part produced by the casting method may be defective and have a vacuum. However, finally, in order to reach the desired part, machining must be done on its surface.

Advantages

Increased strength and resistance: In the forging method, due to shaping by pressure and hammering, the strength and strength of the final product increases, and the vacuum in it is also eliminated.

High quality and precision: In this method, metal ingots are produced with high precision and precise sizes.

Increased lifespan: Due to the increase in the structural quality of the product, its lifespan also increases.

Reducing production costs: By using the forging method, we can reduce production costs by reducing waste and increasing production speed.

Disadvantages

Expensive equipment: Forging requires expensive equipment and equipment.

Requires skill and expertise: It requires expert technicians and experts to monitor and produce high quality and accurate products.

Making noise: The forging process is always accompanied by noise, that’s why people working in this environment should use safety devices such as ear protection. Also, to prevent noise for the surrounding environment, anti-noise structures should be used.

Environmental Impacts: Forging may lead to the creation of greenhouse gases and other pollutants that require proper management and control.

Final word

Finally, it should be said that forging is a complex but precise process to produce metal ingots with high resistance and strength, which requires high-quality and expensive devices. However, AzinForge company, using machines such as hydraulic press (4000 tons), counterblow hammer (kJ400), 5-meter ring rolling and carousel, has been able to produce knowledge-based products that can compete with world-renowned companies in the field of business and The new work has taken a big step towards self-sufficiency and development of our beloved country, Iran.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.