Introduction

RF and RTJ flanges are two types of standard flanges that are used to connect pipes or industrial equipment. These two types of flanges are more important due to their special features and for correct selection and optimal use in industrial projects, including: Oil and gas, petrochemicals, water and sewage are very important. In the rest of this article, the definition of RF and RTJ flanges and their differences such as: Surface design, thickness, pressure and temperature, installation and commissioning, gaskets, surface elevation and price.

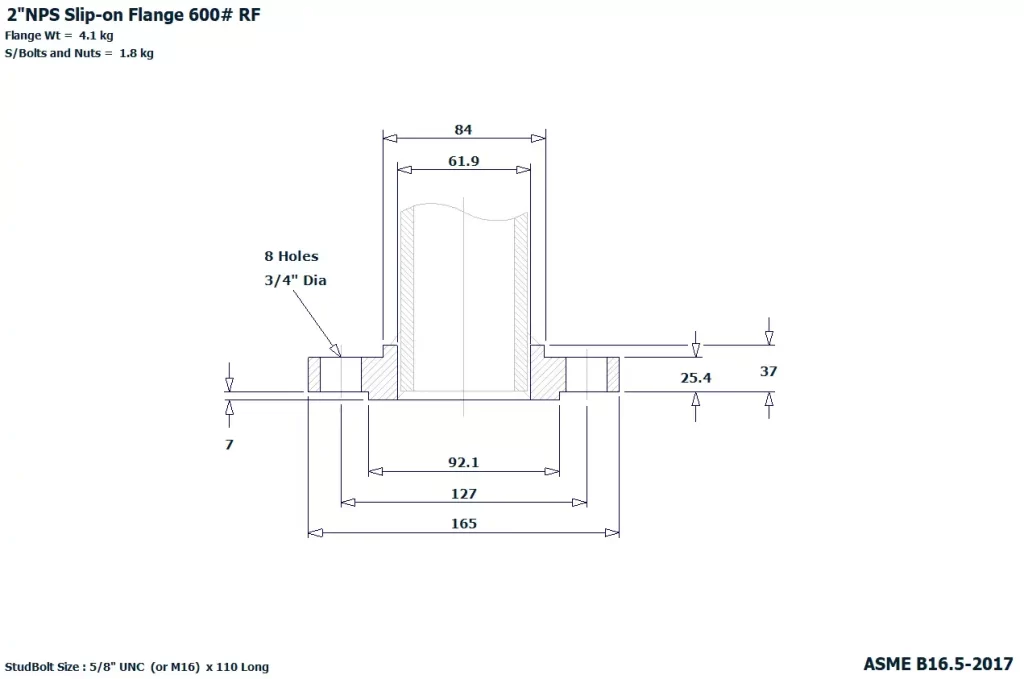

Raised Face (RF) Flange

Raised Face (RF) Flange is one of the standard flanges used to connect pipes and equipment in the piping system. This type of flange has a raised surface. A gasket is placed on this surface during connection to make this connection tight and sealed. This flange is suitable for medium to high pressures and is commonly used in oil and gas systems.

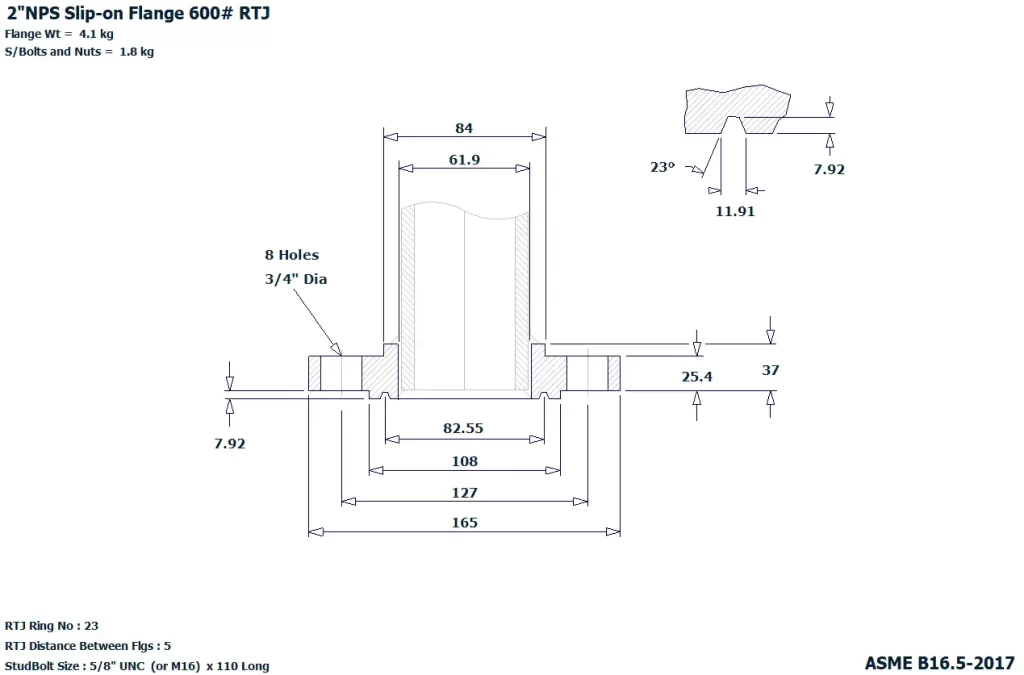

Ring Type Joint Flange

Ring Type Joint (RTJ) Flange is also a type of flange specially designed for high pressures and high temperatures. On the surface of this flange, as you can see in the picture above, there is a recess in which a metal ring washer or gasket is placed inside this recess to provide a tight connection and sealing. For this reason, this type of flange is suitable for oil and gas systems, chemical and petrochemical industries, and it is very strong and safe in terms of connection.

The difference between RF and RTJ flanges

Surface design

Raised RF Flange: It has a raised face around its central bore. This raised face is used to make a tight connection with the gasket. Also, this Raised Face (RF) helps to distribute the pressure uniformly on the surface.

Ring Type Joint (RTJ) flange: RTJ flange has a special surface called Mating Surface. This surface is conical and ring-shaped and is used to create a tight and leak-proof connection between two RTJ flanges.

Thickness

RTJ flanges are thicker than RF flanges. This is due to the need for special metal nuts and higher quality bolts in RTJ flanges, which need to be thicker to provide a tight, leak-free connection. The thickness of flanges is determined based on standards such as ASME/ANSI or API, and there are specific values for thickness for each type of flange. But in general, we can say that Ring Type Joint (RTJ) flanges are thicker than Raised Face (RF) flanges due to the need for stronger metal nuts and bolts.

Pressure and temperature

RF Flange: Usually used in moderate pressure and moderate temperatures.

RTJ Flange: Commonly used in high-pressure and high-temperatures.

Installation

RF Flange: The RF flange is relatively easier to install because this type of flange has a raised face on which the gasket fits and can be easily attached to the pipe or equipment.

RTJ flange: But installing the flange with the surface of the RTJ requires more precision. This type of flange has a connecting ring that must be carefully positioned to ensure a tight and leak-proof connection.

Gasket

RF Flange: RF Flange: The gasket of this surface is flat or grooved. Its material can be graphite, PTFE.

RTJ flange: But installing the flange with the surface of the RTJ ring joint requires more precision. This type of flange has a connecting ring that must be carefully positioned to ensure a tight and leak-proof connection.

The height of the surface elevation

The height of the front projection in flanges is usually determined according to various standards such as ASME/ANSI or DIN. This height may be different for both RF or RTJ flanges.

Generally, the height of the front projection for RF flanges is about 2 mm to 7 mm (according to ASME B16.5 standard). But for RTJ flanges, the height of the front projection is usually higher. For example, according to the ASME B16.5 standard, the height of the protrusion is from 6.35 mm to 20 mm according to the size of the flanges.

Contact the sales department (central) in AzinForge for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Price

The price of RF and RTJ flanges depends on their size, material and tolerable pressure. However, RTJ flanges are generally more expensive than RF flanges. The reason for this is that RTJ flanges are designed for high-pressure and high-temperature environments. In general, RF flanges can be used for environments with normal pressure and temperatures. On the other hand, it is better to use RTJ flanges for environments with high pressure and temperatures.

RF and RTJ flanges connection

It is not possible to connect RF and RTJ flanges to each other, because these two types of flanges have fundamental differences in structure and installation method. The RF flange has a raised face while the RTJ flange has a connecting ring.

Therefore, due to these differences, it is not possible to connect RF and RTJ flanges to each other, and they need to use flanges with similar structures.

Some flange production standards in AzinForge

ASME B16.5 – ASME B16.34 – ASME B36.10 – ASME b36.19 – MSS SP 6 – MSS SP 9 – MSS SP 25 – NACE MR 0175 – ASTM A105 – ASTM A182 – ASTMA350

Conclusion

In summary, the main difference between RF and RTJ flanges is their appearance, their sealing mechanism, and their installation and maintenance requirements. RF flanges are suitable for medium pressure applications and use a soft gasket for sealing, while RTJ flanges are designed for high-pressure and temperature applications and use a metal ring gasket for sealing. Also, RTJ flanges require more precision during installation to ensure proper alignment of the metal ring gasket. Understanding the differences between these two types of flanges is essential to choosing the right type of flange for a specific application, to ensure reliable operation and safety of the piping system. Contact AzinForge experts in the sales unit for advice and to order the flange you want.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.