Introduction

A Long Weld Neck Flange is a connector that has a long neck for welding to pipes or equipment in a piping system. These types of flanges are usually used to connect pipes, pumps, valves and other equipment. In this article, we discuss the features, application, standards and dimensions of welding long neck flange.

Long Weld Neck Flange

As we mentioned at the beginning, the Long Weld Neck flange is used to connect to pipes and other equipment. These flanges are usually made of carbon steel, alloy steel and stainless steel and are suitable for high pressure and high temperature applications and pipelines.

AzinForge Company, having the most advanced equipment in the world, including a 5-meter rolling ring, has the ability to produce all kinds of rims and flanges up to 5 meters in diameter. It is worth noting that all flange products produced in AzinForge Company are made by closed die forging, open die Forging and ring rolling method.

Features of Long Weld Neck Flange

The features of this flange include the following:

1. Long neck: This type of flange has a long neck, which provides a strong and stable connection between the pipe and the equipment.

2. Welding: Long Weld Neck Flanges are connected to the pipe using a welding process, which makes the connection very strong and durable.

3. Pressure and temperature: These flanges are usually made of resistant materials such as steel or stainless steel and are suitable for high pressure and temperature resistance.

4. Types of dimensions: This type of flange is produced in various dimensions and sizes so that it can be connected to all types of pipes and equipment. In the continuation of this article, we will also examine their dimensions. (AzinForge also produces non-standard flanges according to customer requests)

Application of Long Weld Neck Flange

Long Weld neck Flanges have high strength and strength to withstand high pressure and temperatures due to the long neck and welding it to the pipe. For this reason, this part is usually used in oil and gas, chemical, petrochemical and other industries that have high pressure and temperature.

The type of raw materials

Long Weld neck (LWN) flanges are usually made of metallic materials. These materials can include carbon steel (such as ASTM A105 ), stainless steel (such as ASTM A182), or alloy steel. The choice of raw materials depends on the application conditions of the flange, for example, if the flange is exposed to conditions such as high temperature and pressure or certain chemicals, it is very important to choose suitable and resistant materials.

1- Carbon Steel: ASTM A105, ASTM A350/LF2

2- Alloy Steel: ASTM A182,F1, F5, F9, F11, F17, F22

3- Stainless Steel: ASTM A182/F6, F304, F316, F321, F347, F348

Standards and dimensions

Long Weld Neck flanges are made according to different standards. Some of the most famous standards are as follows:

1. ANSI/ASME B16.5:

In the ASME B16.5 standard, Long Weld Neck flanges of various types and sizes are defined to suit the needs of various industries and applications. The sizes stated for this flange in ASME B16.5 are:

| Classes | Sizes |

|---|---|

| 150, 300 | 1/2 to 24 inches |

| 400, 600 | 1/2 to 12 inches |

| 900 | 1/2 to 10 inches |

| 1500, 2500 | 1/2 to 4 inches |

The above table was prepared with the help of PipeData pro 14.0 software.

These sizes are defined to adapt to different pressure and temperature conditions in different industries and are very important for choosing the right flange based on working conditions.

Contact the sales department (central) in AzinForge for consultation, purchase and order of the desired product.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

2. EN 1092-1:

This European standard is used for steel flanges.

3. MSS SP-44:

This standard is used for steel flanges with high pressures and temperatures.

4. API 6A:

This standard is used for flanges used in the oil and gas industry, including welded long neck flanges.

Also, there are other national and international standards for Long Weld Neck flanges that may be used depending on the type of application and place of use.

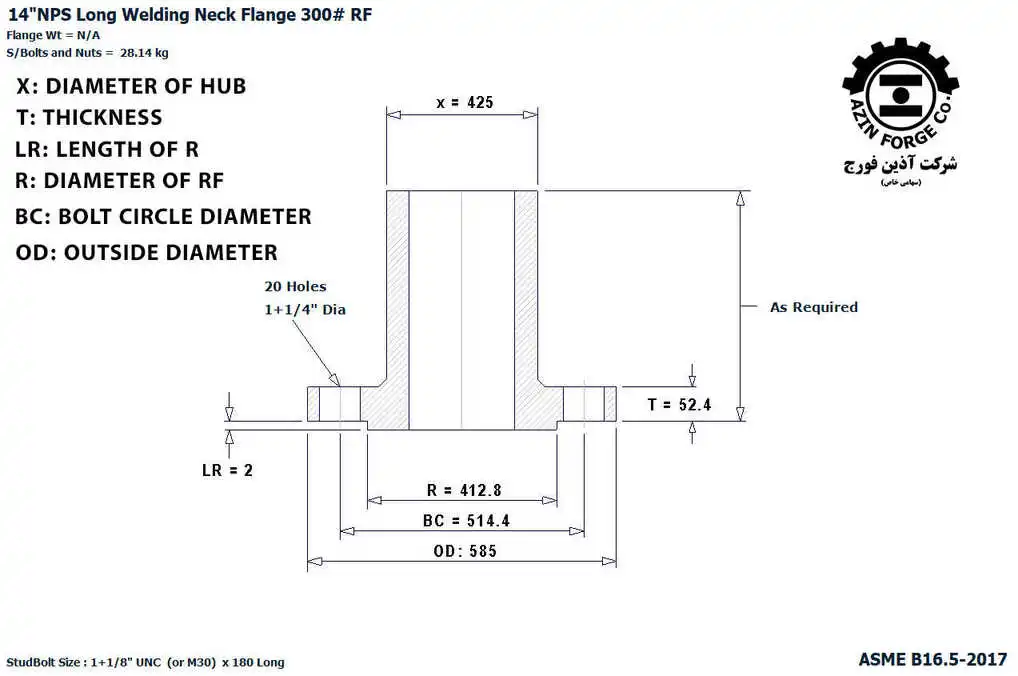

For example, in the image above you can see a schematic of a Long Weld Neck (LWN) flange according to the ASME B16.5 standard (class 300, size 14 inch). This flange is Raised Face (RF) and has the above specifications.

Technical Specifications:

1- Diameter of Hub (X): 425 mm

2- Thickness (T): 52.4 mm

3- Length of R (LR): 2 mm

4- Diameter of RF (R): 412.8 mm

5- Bolt Circle Diameter (BC): 514.4 mm

6- Outside Diameter (OD): 585 mm

7- Bolts and Nuts (Weight): 28.14 kg

Conclusion

As a result, Long Weld Neck Flanges are a type of flange that are used to connect pipes or equipment together. Due to its long neck, this type of flange allows connection to the pipe or equipment and is connected to the system by welding. These flanges are designed for use in high pressure and temperature conditions.

Due to different types of classes and sizes, Long Weld Neck Flanges can be used to adapt to different working conditions and in different industries. The correct selection of these flanges based on the working conditions and relevant standards is very important so that the connections are made correctly and the system works correctly.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.