Introduction

Flanges are considered one of the vital components in industrial piping, which play an important role in connecting, blocking and safety of fluid flow. Each type of flange has its own characteristics and standards depending on the application and working conditions. Among them, blind flange has a special place, because it is responsible for blocking the path of the pipe or equipment and preventing fluid leakage.

In this article, we will examine blind flanges. Also, in the rest of this article, we will discuss the types of blind flanges (BL) in terms of surface, features, applications, standards and technical specifications, and finally, their advantages and disadvantages.

Article: What is a flange? Types | How to stamping

Last update: 11/06/2025 | Approximate study time: 9 min

What is a Blind Flange?

Blind flange is a type of flange that is used to close a pipe or pipe system. This flange is without holes and is used to block a pipe connection or part of a piping system. and also, this flange is used to prevent the passage of liquid or gas from a specific point in the desired system.

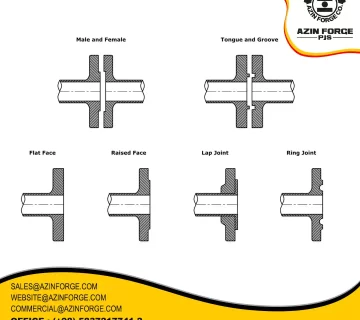

Types of blind flanges in terms of surface

Blind flange is divided into several types in terms of surface:

1. Blind Flange (Flat Face): In this type of flange, the inner surface of the flange is smooth and it is used for connections with low and medium pressure.

Article: the best flange manufacturers in Iran (AzinForge)

2. Blind Flange (Raised Face): In this type of flange, there is a raised edge on the inner surface of the flange, which is used to create a tight connection with the gasket. This type of flange is used for high-pressure connections.

3. Blind Flange (Ring Type Joint): This type of flange has a deep groove for the placement of vertebral cuts. These flanges are used for high-pressure and high-temperature connections and are commonly used in the oil and gas industry.

Features of or Blind Flange

1. Inlet or outlet: There is no hole or inlet and outlet in the flange, in other words, the flange is without holes.

2. Closing the pipeline: Blind flange is usually used at the end of a pipeline or in places where there is a need to close and seal the pipeline.

3. Pressure and temperature: This type of flange is suitable for flange connections with high pressure and temperatures.

Article: RTJ Flange, its application in industry

4. material: blind flange is usually made of carbon steel or stainless steel or alloy steel.

5. Repairs: Blind flanges and spectacle flanges are used during pipeline repairs.

Application of Blind Flange

Blind flange is used in industry as a connection piece that is used to close or block a pipe or pipeline. These flanges are used as a cover for the end of a pipe or flange connection and are used in cases where there is a need to temporarily connect or block a pipe for repair or maintenance. Also, these flanges can be used to create an access point for testing and measuring pressure and temperature in piping systems.

Standards and technical specifications

ASME B16.5 | ASME B16.47 (Series A, Series B) | API 6A | DESTEC | EN 1092-1

The ASME B16.5 standard is available in two types, RTJ and RF, from 1/2 to 24 inches and has classes of 150, 300, 400, 600, 900, 1500 and 2500.

Also, according to the ASME B16.47 Series A standard, the size of the blind flange is from 26 inches to 60 inches and has class 150, 300, 400, 600, 900.

Contact our specialists in the sales unit for advice, order and purchase of your desired product and inquire about the price.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Technical specifications of Blind Flange

1. Size: The size of the blind flange is determined by the inside diameter of the pipeline or flange connection.

2. Pressure: this flange must be able to withstand the pressure of the pipeline or flange connection.

3. Temperature: The blind flange must be able to withstand the temperature of the pipeline or flange connection.

4. Material: Blind flange can be made of different materials such as carbon steel, stainless steel, alloy, etc.

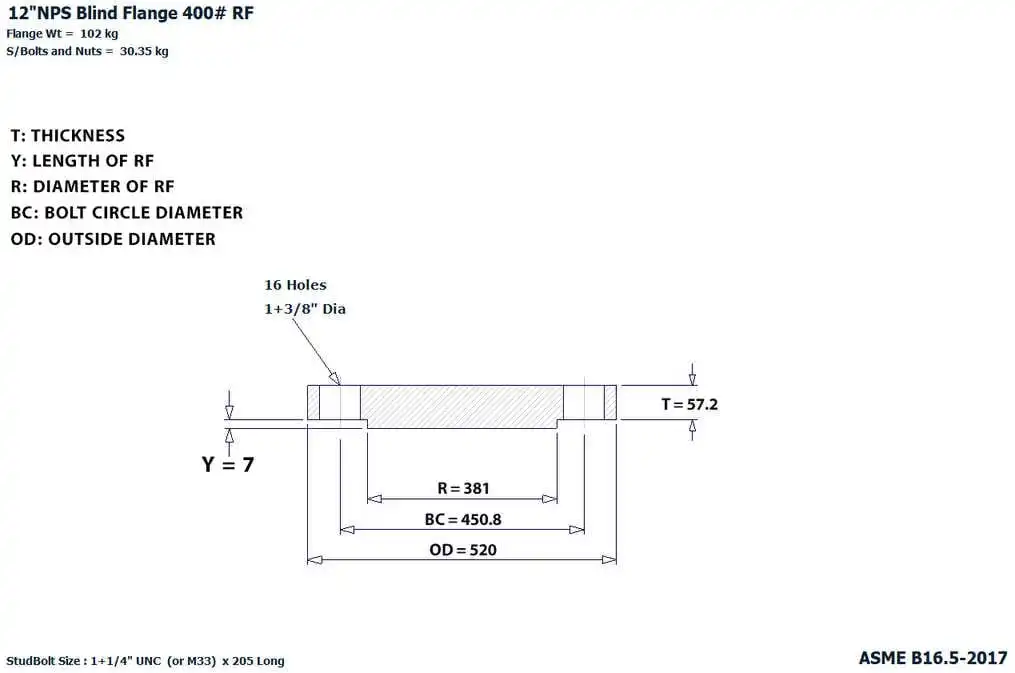

Technical specifications in picture number 4:

For example, the specifications in Figure 4 (according to ASME B16.5, size 12 inches, class 400) are as follows:

1. Thickness (T): 57.2 mm

2. Length of RF (Y): 7 mm

3. Diameter of RF (R): 381 mm

4. Blot Circle Diameter (BC): 450.8 mm

5. Outside Diameter (OD): 520 mm

This flange also has 16 screw holes with a diameter of 1+1/3 mm and according to the ASME B16.5 standard, the weight of the blind flange is 102 kg and the weight of its bolts and nuts is 30.35 kg.

Article: What is Threaded Flange? | Sizes | Class

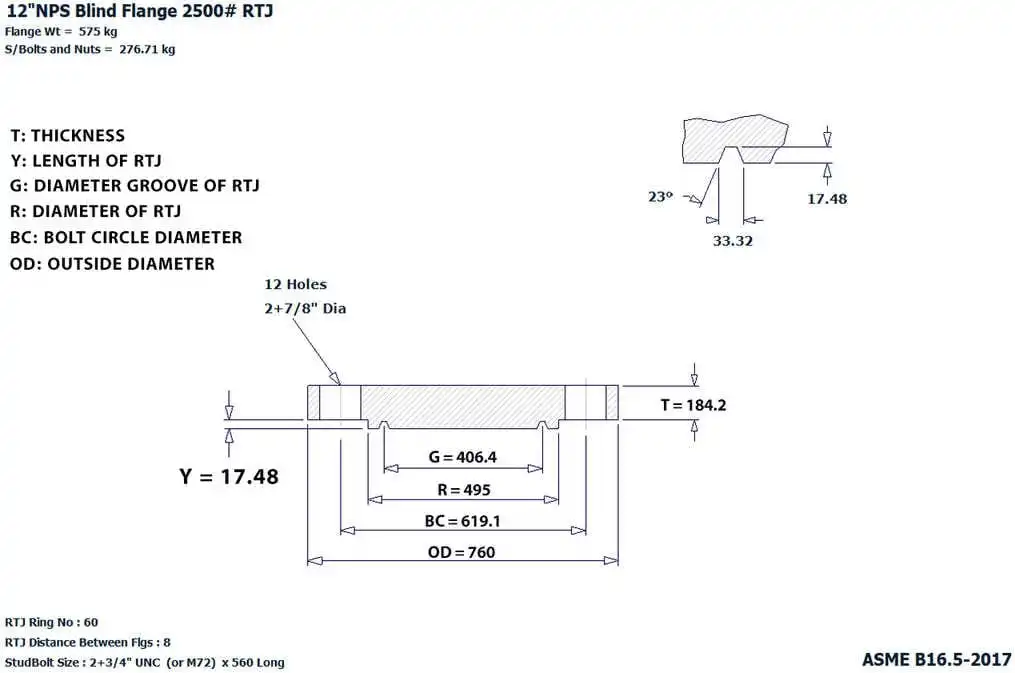

Technical specifications in picture number 5:

In picture number 5, for example, we have a blind flange with the following specifications (according to the ASME B16.5 standard, size 12 inches, class 2500):

1. Thickness (T): 184.2 mm

2. Length of RTJ (Y): 17.48 mm

3. Diameter Groove of RTJ (G): 406.4 mm

4. Diameter of RTJ (R): 495 mm

5. Bolt Circle Diameter (BC): 619.1 mm

6. Outside Diameter (OD): 760 mm

This flange also has 12 screw holes with a diameter of +2.7/8 mm, and according to the ASME B16.5 standard, the weight of this blind flange is 575 kg, and the weight of its bolts and nuts is 276.71 kg.

Advantages and Disadvantages

Advantages:

1. Temporary closure: this flange is used for temporary closure at the end of a pipeline or flange connection. This flange prevents material from entering or leaving the pipeline until it is necessary to access the pipeline again.

2. Creating safety: the use of blind flanges can increase the safety of pipelines, because it prevents the entry of unauthorized materials into the pipelines.

3. Ease of installation: this flange installation is much easier than other flange connections and does not require welding or screw connections.

Disadvantages:

1. Lack of access: The use of blind flanges may be problematic in cases where there is a need for frequent access to the pipelines because we have to remove the blind flanges to access the inside of the pipelines.

2. Possibility of leakage: There is a possibility of leakage in flange connections if it is installed incorrectly or if an inappropriate seal is used.

3. Cost: Installing a blind flange can be expensive because it requires special fittings and seals to prevent leaks.

In general, the use of this flanges, especially in cases where there is a need to temporarily close pipelines or flange connections, has many advantages, but its disadvantages should also be considered.

Conclusion

Finally, it can be concluded that the blind flange is a temporary and suitable solution for closing connections in pipelines. This type of flange works to temporarily close the pipe or equipment and increases the safety of pipelines. Also, easy installation and no need for welding or screw connections is one of the advantages of this type of flange. However, in cases where there is a need for frequent access to pipelines or there is a possibility of leakage, the use of blind flanges may be problematic. In general, the use of blind flanges should be done carefully and considering the specific conditions of each project to ensure the best performance and safety of pipelines.

Sales department:

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.