Weld Neck Flange

Weld Neck Flange is an industrial fitting used to securely connect pipes in a piping system. This type of flange is usually used to connect pipes to valves, flanges or other equipment. The main feature of this type of connection is the increased strength and stability of the connection due to the long welding neck.

The disk surface of this flange can be a flat face, a raised face flange, or a ring type joint (RTJ) surface.

Features:

1. Neck: A weld neck flange has a neck for welding to pipes or other equipment

2. Pressure and temperature: A weld neck flange is designed for use at high pressures and temperatures.

3. Connection: Provides a strong and durable connection to pipes or other equipment by welding.

4. Resistance: Depending on the standard type, it can be resistant to corrosion and pressure.

5. Application: Can be used in various industries including oil and gas, petrochemical, power plants and other industries.

Standards:

Weld Neck Flange Standards include various standards that are used for different types of flanges. Some of these standards are:

1. ANSI/ASME B16.5: American Standard for Dimensions and Measurements of Flanges and Pipe Fittings.

2. EN 1092-1: European Standard for Flanges and Pipe Fittings.

3. JIS B2220: Japanese Standard for Dimensions and Measurements of Flanges.

4. DIN 2633: German Standard for Flanges and Pipe Fittings.

Each of these standards has its own specifications and regulations that are important for use in different industries.

Showing 1–12 of 23 results

-

Weld Neck Flange (CL-150-RF-18″)

Read more -

Weld Neck Flange (CL-150-RF-20″)

Read more -

Weld Neck Flange (CL-150-RF-28″)

Read more -

Weld Neck Flange (CL-150-RF-3/4″)

Read more -

Weld Neck Flange (CL-150-RF-4″)

Read more -

Weld Neck Flange (CL-150-RF-6″)

Read more -

Weld Neck Flange (CL-1500-25DN)

Read more -

Weld Neck Flange (CL-1500-3/4″)

Read more -

Weld Neck Flange (CL-1500-RTJ-2″)

Read more -

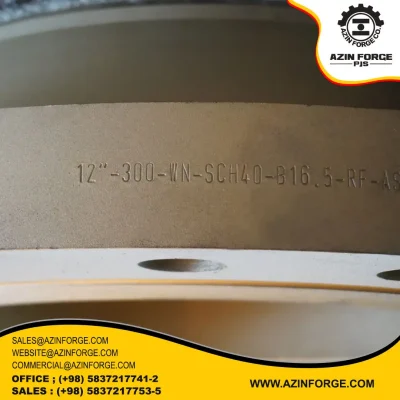

Weld Neck Flange (CL-300-RF-12″)

Read more -

Weld Neck Flange (CL-300-RF-15DN)

Read more -

Weld Neck Flange (CL-600-RF-2″)

Read more