Introduction

A flange is a metal piece that is used to connect pipes to each other and One of the flanges used in the piping system to control and measure the flow of fluids is the Orifice Flange. In the rest of this article, we will talk about the types of orifice plates, its components, the characteristics and use of orifice flanges, the installation guide for orifice flanges, and finally the conclusion.

- 1 Introduction

- 2 What is a Orifice Flange?

- 3 Types of Orifice Flange Plates

- 4 1. Concentric Orifice Plate

- 5 2. Eccentric Orifice Plate

- 6 3. Seqmental Orifice Plate

- 7 4. Quadrant Orifice Plate

- 8 5. Multi-hole Orifice Plate

- 9 Various components of orifice flange

- 10 Orifice flange features

- 11 Use of orifice flange

- 12 Orifice flange installation guide

- 13 Conclusion

- 14 AzinForge Flanges

What is a Orifice Flange?

An orifice flange is a type of flange that has a central arm with a precise diameter that is used as an orifice to control the flow of liquid or gas. This type of flange is used as a standard connection to connect various pipes or equipment and is usually used in high-pressure systems or in environments with high temperature and pressure. The orifice flange usually limits the flow in the direction of measurement with the help of the orifice plate and the central arm.

Types of Orifice Flange Plates

1. Concentric Orifice Plate

Concentric orifice plate refers to the alignment of the orifice hole with the centerline of the flange. A concentric orifice flange has an hole located exactly in the middle of the flange, creating a concentric circle. This ensures that the orifice flange plate used to measure the flow rate is precisely aligned with the centerline of the piping system. The center plate has two drain holes. One of them is a small drain hole that is used to drain liquid or deposits from inside the system or device. Another hole is the Vent hole, which is used to remove air from the system or device.

The concentric design is critical to accurate flow measurement, as it helps minimize disturbances and pressure drop around the orifice plate. This allows for a more reliable and consistent flow and is therefore a common choice in applications where accurate flow measurement is essential for process control and optimization.

Concentric orifice plates are used in various industries, including oil and gas, petrochemical, water treatment and industrial processing industries, where accurate flow measurement is essential for process control and optimization.

2. Eccentric Orifice Plate

Eccentrice orifice plates refer to the orifice hole not aligning with the centerline of the flange. A eccentrice orifice flange plate has a hole that is neither in the center of the flange nor concentric circularly. This type of design may be used in some cases, but is not usually used for accurate current measurement. This type of flange may be suitable for certain applications, but may reduce measurement accuracy due to the lack of exact alignment with the centerline of the piping system.

3. Seqmental Orifice Plate

Segmental orifice plate is a type of orifice plate for measuring fluid flow. This part plate has a semicircular hole through which the flow of gas or oil passes. Piece orifice flanges are usually used in industrial applications where accurate flow measurement and control is necessary. They are often used in processes such as oil and gas, petrochemical and industrial fluid control.

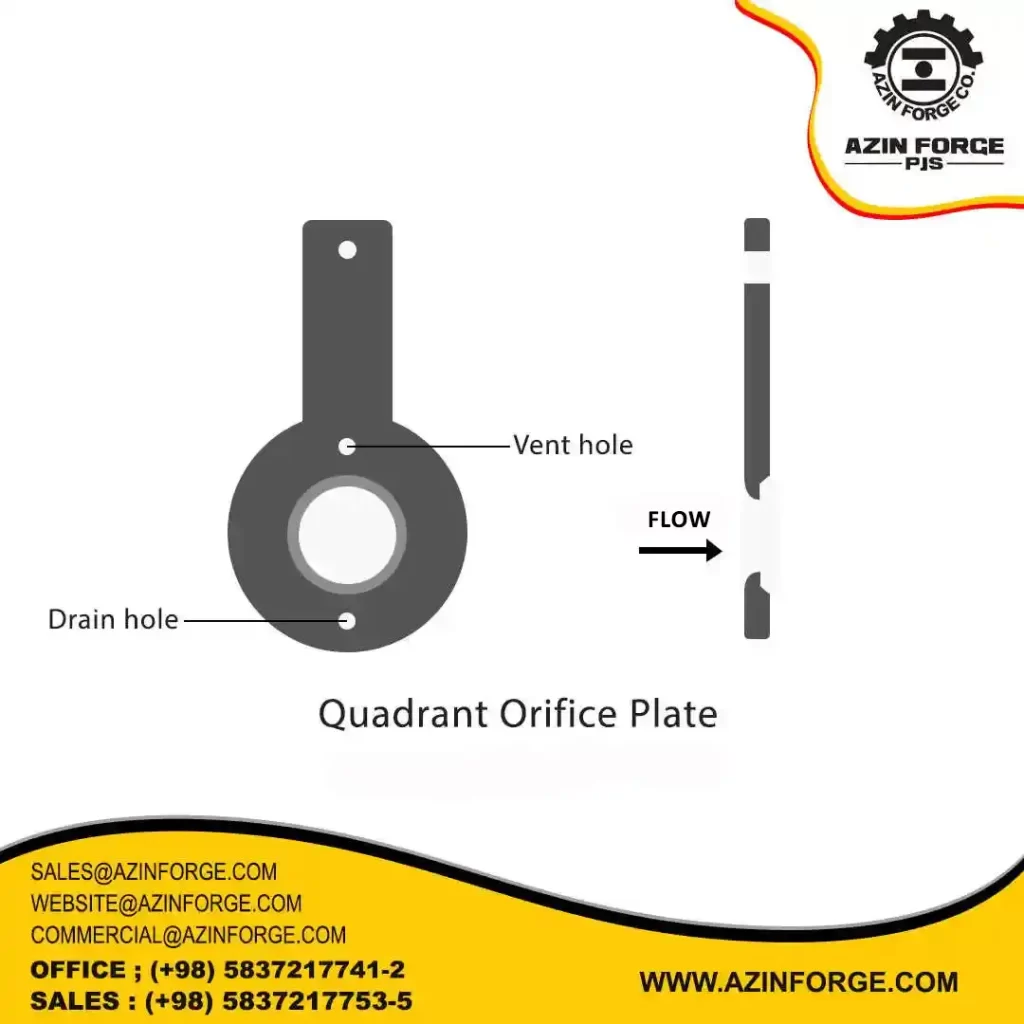

4. Quadrant Orifice Plate

Quadrant orifice plate is a mechanical part that is used to control the flow of fluids. This plate has a central arm which is divided into four parts and that is why it is called Quadrant Orifice Plate.

The use of square orifice flange plate is used to control and measure fluid flow in various industrial systems, including oil and gas, chemical, petrochemical, and water and sewage. This screen is usually made of stainless steel or carbon steel and has high accuracy in measuring fluid flow.

5. Multi-hole Orifice Plate

A multi-hole orifice plate usually has several small holes or orifices arranged in a specific pattern to accurately measure fluid flow through the system. These orifices are often combined with differential pressure sensors to calculate the flow rate. In addition to accurate flow measurement, multi-hole orifice flange plates are also designed to provide easy installation and maintenance. They are available in different materials and pressure ratings to suit different applications and operating conditions. This type of flange is commonly used in the oil and gas, chemical processing and water treatment industries, where accurate flow measurement and control is critical.

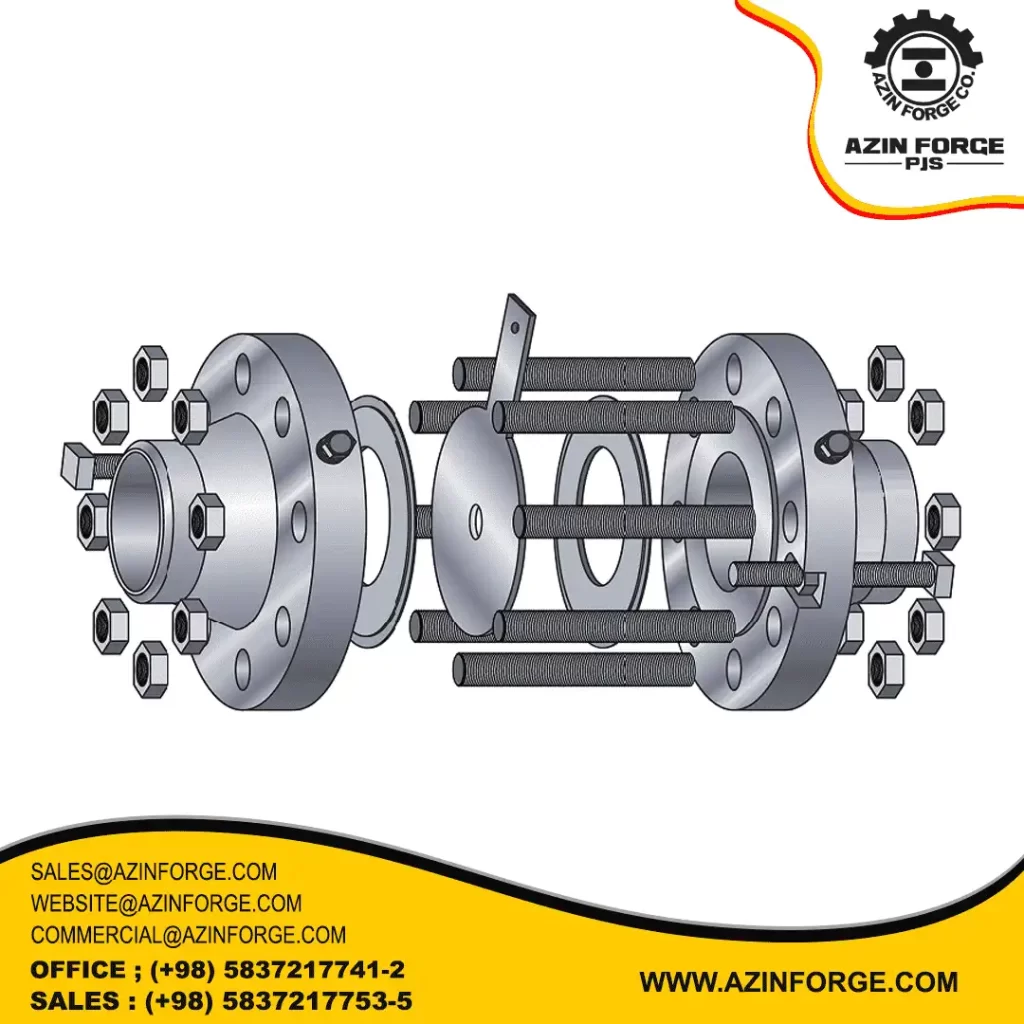

Various components of orifice flange

1- Flange:

This flange is the main part that connects the orifice plate assembly to the piping system. These components provide an interface to connect the orifice plate assembly to the pipeline.

2- Thin plate (Plate):

A thin plate with one or more holes designed to regulate the orifice pressure that allows flow measurement.

3- Gaskets:

A gasket or washer used to ensure a tight, leak-free connection between flanges and a thin plate.

Article: Raised Face Flange (RF) | Application | Materials

4- Bolt & Nut:

Fasteners used to secure the orifice flange assembly to the pipeline. These are necessary to maintain the integrity of the flange connection.

5- Jack Screws:

These screws are used to help separate the flanges to inspect or replace the orifice plate.

6- pressure gauge hole:

The small holes on this Flange are used to connect the pressure gauge device and place it in the path of movement of fluids or gas to measure the pressure of the material passing through the pipeline of the piping system.

These components work together to create a reliable and accurate flow measurement system in industrial processes.

Orifice flange features

Orifice flange features include the following:

1. Appropriate design:

This type of flange is designed for the installation and use of a thin orifice plate and it must be of suitable materials and dimensions for this purpose.

2. Proper connection:

This flange must be able to connect to pipe or other devices and can provide a tight connection.

3. Safety and strength:

Orifice flange must be made of suitable materials and standards to withstand different pressures and temperatures in order to have the required safety and strength.

4. Corrosion resistance:

Since this flange is in contact with various liquids, it should be made of materials that have good corrosion resistance.

5. Relevant standards:

This type of flange must comply with the relevant standards in order to have proper quality and performance.

These features can vary depending on specific needs and user environment, and other features may be required for each specific application.

Use of orifice flange

Orifice flange is used in various industries for flow measurement and pressure control applications of liquids or gases. Some of its main uses are:

1. Flow measurement:

This flange is used for accurate measurement of liquid and gas flow in piping systems and industrial equipment. The orifice plate is installed in the flange and the liquid flow passes through it, and by measuring the pressures and temperatures, accurate information of the flow can be obtained.

2. Pressure control:

Orifice flange is also used as a pressure control method for liquids and gases. By adjusting the size and shape of the orifice plate, the pressure and flow of liquids can be controlled.

3. Prevent leakage:

The outer surface plate of this flange restrains and evens out the internal pressure and volume and minimizes fluid leakage. This feature prevents leakage and maintains the quality of the connection.

4. Industrial applications:

Orifice flanges are used in oil and gas, petrochemical industries, power plants and other industries to measure and control the flow of liquids and gases.

5. Maintenance:

This flange provides easier maintenance due to its detachable structure using bolts and nuts. If you need to replace or repair pipes or parts, the connections can be easily disassembled and reconnected.

In general, Orifice Flange is an important tool for accurate flow measurement and pressure control in industrial systems and is used in some very critical industries.

Orifice flange installation guide

Installing an Orifice Flange should be done carefully and following the manufacturer’s standards and instructions. Here are some general steps to install the Orifice Flange:

1. Preparation:

First, clean around the Flange and related pipes or equipment to avoid any particles or contamination. Also make sure the orifice plate is properly and accurately manufactured.

2. Installation of orifice plate:

Carefully insert the orifice flange plate into the flange and make sure it is properly seated by the shiny material.

3. Installing and tying labels:

Some Orifice Flanges have labels that show measurement information. If there are such tags, make sure they are carefully installed and tied.

4. Fastening the brackets:

If needed, carefully tighten the Orifice Flange Brackets so that the Orifice Flange Plate is in its proper position.

5. Final settings:

After installing the Flange, make sure that all skills and connections are done accurately and timely and there are no defects.

In any case, it is better to carefully read and follow the manufacturer’s instructions and relevant standards to install Orifice Flange. Also, if you need special settings for specific applications, it’s best to consult an expert.

Conclusion

An orifice flange is a piece of industrial equipment used to measure fluid flow in a piping system. These flanges have an orifice plate that acts as a flow restrictor. Some of the most important points about Orifice Flange are:

1. Installation and adjustment:

Installation of Orifice Flange requires precision and technical knowledge. Manufacturer’s instructions and relevant standards must be followed.

2. Accurate measurement:

Orifice flanges are used to accurately measure the flow of fluids and must be installed carefully to obtain the correct measurement.

3. Use in different programs:

Orifice flanges are used in various industrial applications including oil and gas, petrochemical, and other industries.

4. Flow management:

Orifice flanges act as a fluid flow management tool and can help improve the efficiency of piping systems.

5. Technical points:

To install and use the Orifice Flange correctly, you should pay attention to technical points such as choosing the right size and material.

Due to the importance of the technical features and proper installation of the Orifice Flange, it is always best to consult with engineering and industrial professionals to ensure that the process is done correctly.

AzinForge Flanges

AzinForge Company is the best and largest flange manufacturer in Iran. Due to the existence of a hydraulic press 40MN (4000 tons), it has the ability to produce all kinds of flanges in the form of closed die forging from 1/2 to 30 inches, as well as the ability to produce all kinds of flanges in the form of open die forging from 30 to 120 inches in accordance with the standards of the oil and gas industry. has it.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.