Introduction

AzinForge Company, with the largest ring rolling machine in Iran, is able to produce industrial rings up to 5000 mm in diameter, 18 tons in weight, and 1500 mm in height. Industrial rings have diverse and important applications in various industries and are used in various industries including oil and gas, petrochemicals, power plants, mines, cement, etc. Alloy steel refers to steel in which, in addition to iron and carbon, other alloying elements such as manganese, nickel, chromium and molybdenum have been added. In this article, we will examine industrial rings made of alloy steel.

Product: View some of the industrial rims produced at Azin Forge

| Contact number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Last updated: 11/08/2025 | Approximate reading time: 5 minutes

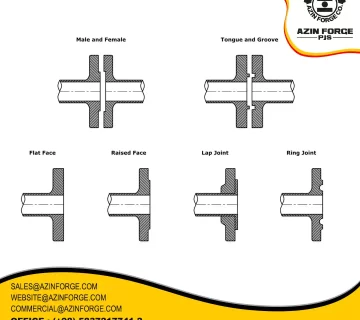

Article: What is a flange? Its types | Standards

Industrial rings

Alloy steel is one of the most widely used materials in the manufacture of industrial rings due to its high strength, hardness, flexibility, and sometimes high resistance to corrosion.

Stages of industrial ring production

1- Initial forming: Steel ingots are converted into the initial form (preform) of the desired rings.

2- Rolling with a ring rolling machine: The raw materials on which the initial forming has been performed are transferred to the ring rolling machine and are formed into the desired shape according to the drawing.

Article: Forging: Examining Process Types

3- Heat Treatment: AzinForge Company, utilizing various heat treatment equipment, including wagon and box furnaces, quench pools, is able to perform various heat treatments on parts, including the following:

- Annealing: Performed to reduce internal stress and soften the steel.

- Hardening/Quench and Temper: Steel is heated to high temperatures and then rapidly cooled to increase hardness.

- Normalizing: This process involves heating the steel to a temperature above the phase transformation temperature and then cooling it in air. The purpose of normalizing is to improve mechanical properties such as strength and hardness, as well as to create a fine-grained and uniform structure. Normalizing is used in particular to eliminate the effects of previous operations such as hot or cold working, and to achieve a homogeneous metallurgical structure.

- Tempering: After hardening, the part is heated to temperatures below the phase transformation temperature and then slowly cooled to achieve the right balance between hardness and toughness.

4- Machining: The rings are carefully machined according to the relevant part drawing to achieve accurate dimensions and a suitable surface.

Product: View forged products of Azin Forge Company

| Contact number | |

|---|---|

| 058-37217753-5 | sales@azinforge.com |

Method of producing high-pressure rings

1- Forging

In the forging method, the metal piece is first heated and then shaped under the pressure of a die. This process creates a compact and resistant grain structure and is the best choice for producing high-pressure industrial rings.

Advantages:

High strength against pressure and impact

Excellent resistance to cracking and fatigue

Precise machining capability after forging

2- Ring Rolling

In this method, the metal is heated and rolled between two rollers to form a ring shape.

Ring rolling is mostly used for large rings with a diameter of more than 5000 mm.

Features:

Even stress distribution

Reduction in material waste

Smoother surface than traditional forging

3- Machining

For rings with small dimensions or low pressure, cutting and machining of steel billets may be used. Although this method is more economical, it has lower final strength.

Applications of industrial rings

Forged rings and high-pressure steel are used in various industrial sectors, including:

- Oil and gas industries: in flange connections, valves, gas transmission lines

- Petrochemical and refinery: for steam and high-pressure systems

- Power plants: in turbine and boiler equipment

- Hydraulic systems: in cylinders and high-pressure connections

- Food and pharmaceutical industries: with corrosion-resistant stainless steel materials

Final words

Industrial steel rings play a key role in improving the performance and efficiency of industrial machinery and equipment. Given the appropriate physical and chemical properties of these rings, their correct selection can help increase productivity and reduce maintenance costs. For this reason, it will be of great importance to pay attention to modern technologies in the design and production of these rings in the future.

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.