Introduction

Before examining the use of flanges in wind turbines, it is important to first become familiar with the structure and function of this system. Wind turbines are among the most significant sources of renewable energy, generating electrical power from wind energy. These turbines typically consist of large blades connected to a rotating shaft, a generator, and a support tower.

When the wind blows, the blades begin to rotate, converting wind energy into mechanical energy, which is then transformed into electrical energy by the generator. Typically, wind turbines are installed in regions with strong and consistent winds, and depending on the energy demand, they can be used individually or as part of large wind farms.

Furthermore, to enhance the lifespan and safety of the turbine, advanced control systems are employed. These systems regulate the turbine’s rotational speed and provide protection against strong or sudden gusts of wind, ensuring optimal performance under varying environmental conditions.

Article: Flanges: All About Types, Technical Specifications

Last updated: 2025/11/03 | Approximate reading time: 7 minutes

Turbine structure and components

1- Support Tower

These components, in particular, hold the blades and the axis of rotation in place. Moreover, the support tower is usually made of steel and is typically more than 100 meters high, with an internal ladder that leads to the nacelle. In addition, it provides the necessary structural support to withstand wind loads and vibrations.

2- Wings or blades

These components play a crucial role in converting wind energy into mechanical energy. Specifically, the blades of a wind turbine are shaped like airplane wings and are connected to a rotating shaft. As the wind flows over them, it exerts pressure on the blades, causing them to rotate and drive the turbine’s main shaft.

3- Nacelle

The nacelle is a major and essential part of a wind turbine. It houses the motors, generators, electrical equipment, and control systems used to convert mechanical energy into electricity. Furthermore, the nacelle is responsible for supporting and protecting the internal components of the turbine and is usually positioned at the top of the turbine tower.

4- Control and Lighting System

These components serve to protect the turbine from strong and sudden winds. Specifically, the control and lighting system uses sensors that continuously measure wind speed and direction in order to position the turbine in the optimal orientation for maximum energy production. Additionally, it ensures operational safety and visibility under varying environmental conditions.

Article: Forging: Exploring Different Types of Processes

Components of towers in a wind turbine

These towers are composed of various components, each of which plays an important role in supporting and protecting the turbine. Overall, the main components of wind turbine towers are as follows:

1- Components

Wind turbine towers are made up of several interconnected parts, typically constructed from steel. These components include supports (tubes), beams, diagonal beams, flanges (used to connect the supports together), plates, and other structural elements that collectively form a strong and complex framework.

2- Foundation

The foundation of a wind turbine tower must be capable of withstanding the heavy weight of the turbine as well as strong wind loads. Generally, this foundation is made of concrete or steel and must be both stable and durable.

Flanges are also applied at this stage to connect the supports securely together, ensuring structural integrity between the tower base and the supporting sections.

3- Support Systems

To enhance the strength and stability of the tower, additional support systems such as diagonal beams, beams, flanges, and metal cables are employed. These systems work together to help the tower resist wind pressure, vibrations, and other external forces.

4- Concrete Blocks

To further increase stability and balance, concrete blocks are installed at the base of the tower. Typically, these blocks act as both shock absorbers and foundation reinforcements, helping the structure maintain its position even under heavy wind loads.

Article: The best flange manufacturers in Iran

Flange application in wind turbines

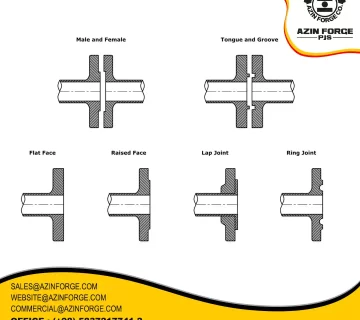

One of the Flange application in wind turbines is to connect different components together. These components may include connecting blades to the turbine shaft, connecting different sections of the tower base to each other, or connecting the final tower base to the wind turbine base.

1- Connecting the different parts of the tower base:

The application of flanges in wind turbines primarily involves connecting the different parts of the tower base to one another. These flange connections must possess sufficient stability and strength to ensure that the wind turbine tower can withstand wind loads and other environmental forces.

In this system, one flange is welded to the end of one tower section, while another flange is attached to the end of the adjacent section. The two sections are then securely connected using bolts and nuts, forming a strong and reliable joint.

As a result of this connection method, maintenance, repair, and transportation of these power-generating structures become significantly easier and more efficient. Moreover, this modular connection system allows for simplified assembly and disassembly, which is particularly beneficial during installation and relocation processes.

2- Connecting the blades to the turbine shaft:

The application of flanges in wind turbines primarily involves connecting the various sections of the tower base to one another. These flange connections must exhibit high stability and mechanical strength to ensure that the wind turbine tower can effectively withstand wind loads and other environmental stresses.

In this configuration, one flange is welded to the end of a tower section, while another flange is attached to the adjoining section. The two sections are then securely fastened using bolts and nuts, resulting in a robust and reliable joint.

Consequently, this type of connection significantly facilitates maintenance, repair, and transportation of the wind turbine structure. Furthermore, the modular design of the flange system allows for simplified assembly and disassembly, which is particularly advantageous during installation, inspection, and relocation processes.

3- Connecting the final tower base to the wind turbine base:

Another important application of flanges in wind turbines is connecting the tower base to the wind turbine base. These connections must be extremely strong and stable to ensure that both the tower base and the turbine are fully supported and properly aligned.

Overall, flanges in wind turbines are employed to connect various components, thereby enhancing the strength and stability of the entire structure. In summary, the primary uses of flanges in wind turbines include connecting tower sections, attaching blades to the turbine shaft, and joining other critical turbine components.

Some production standards in Azin Forge

These standards cover technical specifications such as diameter, working pressure, material, shape, and dimensions of flanges. Additionally, AzinForge accepts custom orders for flanges and other steel components according to customer requirements.

ASME B16.5 – ASME B16.34 – ASME B36.10 – ASME b36.19 – MSS SP 6 – MSS SP 9 – MSS SP 25 – NACE MR 0175 – ASTM A105 – ASTM A182 – ASTMA350

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.