Introduction

Flanges are one of the most important connections in various industries. They are widely used in the oil and gas, chemical, water and wastewater, and marine industries. These parts are responsible for connecting pipes to each other and providing safe material transfer. For this reason, flanges are used in most piping systems to create strong, safe, and reliable connections. In this article, we are going to review the important points that you should consider before buying and choosing a flange. Following these points will help you choose the best option that suits your needs.

Enter the AzinForge Flange products page

| Contact number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Last updated: 11/09/2025 | Approximate reading time: 11 minutes

What you read in this article:

Flange production

AzinForge, as its name suggests, uses the forging method to produce flanges.

Closed Die Forging is used to produce flanges with sizes from 1/2 to 30 inches.

Open Die Forging is used for flanges with sizes from 30 to 120 inches.

In the production process, the company uses advanced equipment such as a 400kJ canterblow hammer, a 4000-ton hydraulic press, a 5-meter rolling ring, a carousel (vertical lathe), machining and CNC machines to produce its flanges and other products with high quality.

Understanding and examining various forging processes

Buying flanges: brand and quality

Choosing flanges from reputable and experienced brands like AzinForge can guarantee higher quality and reliability in performance. AzinForge is a reputable manufacturer in the field of flanges and industrial equipment and offers its products in accordance with international standards and high quality. For this reason, purchasing flanges from this company can be a safe and reliable option.

However, before purchasing, it is recommended to collect detailed information about the features, standards and quality of the products so that you can make the best possible choice according to your industrial needs.

Flange | Types | Specifications | Dimensions

Flange Standards Review

Before purchasing a flange, be sure to check the relevant standards to ensure the quality, safety, and compatibility of the product with your industrial needs. Common flange standards include ANSI/ASME, DIN, EN, and JIS. Make sure the flanges you are planning to purchase are manufactured in accordance with the standard you are looking for.

1. Japanese Industrial Standards (JIS)

Japanese Industrial Standards or JIS are a set of rules and guidelines developed and published by the Japan Industrial Standards Organization (JISC). The aim of these standards is to increase the quality, safety, and reliability of products and services in the Japanese market.

JIS standards cover various areas such as measurement, raw materials, structure, physical and chemical properties of products, and are used as a comprehensive guide for manufacturers, distributors, and consumers not only in Japan but also in many international markets.

Download PDF of flange size table based on JIS standard

2. ANSI/ASME Standard

The ANSI (American National Standards Institute) and ASME (American Society of Mechanical Engineers) standards are the most important international standards in the field of flange design and manufacturing. These standards were developed by the United States and stand for the American National Standards Institute and the American Society of Mechanical Engineers, respectively.

The ASME/ANSI standard specifies the technical specifications, dimensions, materials, and manufacturing methods of flanges and is used as a comprehensive guide for the design, production, and selection of flanges in piping systems and industrial equipment. This standard is used in various industries to select the appropriate type of flanges for various projects.

Download PDF ASME B16.5 standard (2013)

3. Deutsches Institute fur Normung (DIN) Standard

The DIN standard for flanges is a German standard developed by the German Institute for Standardization (Deutsches Institut für Normung). This standard includes dimensions, features, and technical requirements for flanges for connecting various pipes and equipment.

The DIN standard covers various types of flanges, including welding flanges, neck flanges, threaded flanges, blind flanges, and other common types. This standard specifies details such as exact dimensions, working pressure, material, manufacturing methods, and test and compliance instructions for each type of flange.

The use of the DIN standard in the design and production of flanges standardizes the connections of pipes and industrial equipment and ensures that these connections are made with high quality, safety, and compatibility.

Download PDF of flange size table according to DIN standard

4. European Standards (EN)

European Standards (EN) for flanges are a set of technical standards developed by the European Committee for Standardization (CEN). These standards specify the technical specifications for dimensions, materials, working pressures, test methods, quality assessment, and requirements for the design and manufacture of flanges.

The main purpose of EN standards is to ensure the quality, safety and compatibility of flanges in various industries, including oil and gas, chemicals, and steel. The use of these standards creates coordination and uniformity in the design, manufacture, and use of flanges among European Union member states and helps to facilitate international trade and industrial exchange.

PDF of flange size table according to EN standard

The importance of raw materials in purchasing flanges

The raw materials used in flanges play a significant role in the performance, durability and efficiency of piping systems. Common materials for manufacturing flanges include:

The selection of the appropriate material should be based on the operating conditions, pressure and temperature, corrosion resistance and mechanical properties required so that the flange can ensure optimal performance and the necessary safety in the system.

For advice, ordering your desired products, and price inquiries, contact our specialists at the sales department.

| Contact number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Raw materials play a very important role in the quality and performance of flanges, because the strength, durability and resistance of the flange depend on the type and quality of the materials used in its manufacture. Choosing the right raw materials can have a direct impact on the useful life, safety and efficiency of the flange.

Using high-quality raw materials, in addition to increasing resistance to pressure, temperature and corrosion, also improves the safety of piping systems and industrial equipment. Therefore, special attention should be paid to the careful and informed selection of raw materials when purchasing flanges.

Pressure and temperature rating

Pressure and temperature in flanges are among the most important design and selection parameters and depend on the type of flange material and the application of the system. In fact, each flange has a specific allowable pressure and temperature range based on the type of material, manufacturing method and relevant standard.

1. Pressure:

Flanges are designed to withstand different pressures from low to very high. Each flange class (such as Class 150, 300, 600, etc. in the ASME standard) has its own allowable working pressure. When selecting a flange, it must be ensured that the working pressure of the system does not exceed the allowable pressure of the flange.

2. Temperature:

The working temperature also has a direct impact on the performance of the flange. The ability to withstand temperature depends on the flange material; for example, steel or stainless steel flanges can withstand high temperatures, while PVC or plastic flanges are more suitable for low temperatures.

Therefore, when selecting the appropriate flange for each system, the operating pressure and temperature range must be carefully determined and then a flange must be selected that is fully compatible and safe with these conditions.

Size and connections

The dimensions and types of flange connections can vary depending on the application and the relevant standards. Flange dimensions are usually determined based on international standards such as JIS, DIN, EN and ANSI/ASME. These standards provide detailed dimensional specifications for different types of flanges.

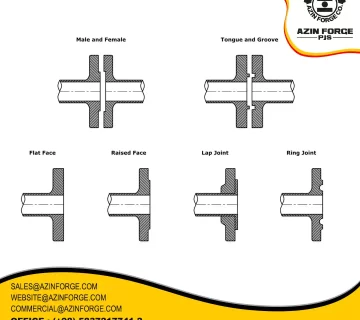

Flange connections also come in different types that are selected based on the type of flange and the system application, including:

- Welded connections

- Threaded connections

- Bolted or rod connections

- Gasketed connections

To ensure safety, durability and proper operation, each flange and its connection type must be compatible and comply with the relevant standard.

Flange price

1. Factors affecting flange prices

The price of flanges is affected by several factors, including: raw material type, dimensions and size, standards used and production technology. Also, market supply and demand also play an important role in determining the price of flanges.

2. Methods for determining flange prices

1-2. Raw material prices:

The price of raw materials such as steel, iron, aluminum and other metals used in flange production has a direct impact on the final price. Changes in the raw material market can increase or decrease the cost of flange production. Therefore, accurate calculation of material costs and consideration of market fluctuations are essential to determine the final price.

2-2. Production costs:

Production costs include items such as labor costs, energy, equipment and machinery, maintenance and other costs related to the production process. Accurate summarization of these costs is of particular importance for calculating the final price of flanges.

3-2. Logistics and transportation costs:

The costs of transportation, packaging, insurance and transportation of the flanges to the final destination should also be included in the price calculations. These costs can have a direct impact on the final price of the product.

To determine the exact price of flanges, the cost of raw materials, production costs and logistics costs must be comprehensively considered. In addition, factors such as the type of material, dimensions, standard and production technology can also affect the final price.

Final words

The correct selection of flanges for piping systems plays an important role in the optimal performance, safety and longevity of the system. To select the right flange, various factors should be considered, including:

- Standards and technical specifications (JIS, DIN, EN, ANSI/ASME)

- Flange construction material and quality

- Pressure and operating temperature range

- Dimensions and type of connections

- Manufacturer brand and reputation

Also, using the advice of experts and industrial engineers can ensure the process of selecting and purchasing the right flange in a more reliable way.

AzinForge Company is one of the leaders in theforging and blacksmithing industry in Iran. By utilizing advanced technologies, the experience and expertise of a specialized and creative work team, and focusing on research and development, this company has been able to achieve a prominent position as the largest manufacturer of rings and flanges in Iran.

Due to the high quality and reliable strength of its products, Azin Forge is known as a reputable and reliable company in the market. Also, the focus on quality control at all stages of production and compliance with international standards demonstrates the company’s commitment to providing high-quality and safe products to customers.

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.