Introduction

Lap joint Flange is a type of metal connector for piping system that is used in various industries. In this article, we are going to review the lap joint flange, its applications, standards, advantages and disadvantages.

What is Lap Joint Flange?

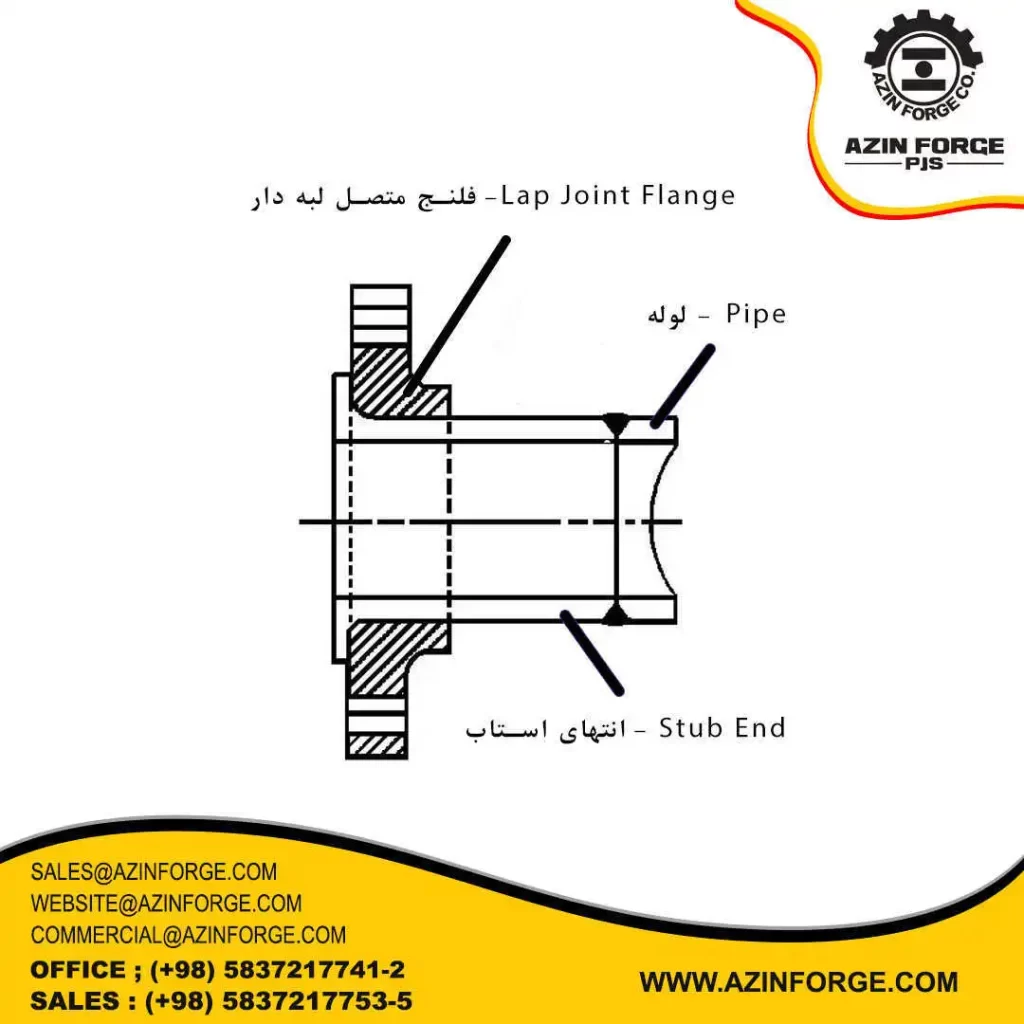

This flange, which is a type of pipe connector that consists of two parts. One is the Stub End which is welded to the pipe and the other is the Lap Joint Ring which we can rotate to adjust to connect with the flange of the same shape. Also, this part has other names such as Van Stone and Stub Flange.

Structure of Lap Joint Flange

Lap Joint Flange consists of two parts, one is the Stub End and the other is the Lap Joint Ring. As you can see in the pictures above, the Stub End has an edge that makes the Lap Joint Ring to be placed on it and connected to the other flange by means of bolts and nuts. Also, Stub End is welded to the pipe or other connections. For this reason, this type of connectors is useful in large sizes and places where it is difficult to adjust the flanges.

Applications of lap joint flange

It is usually used in industries that require frequent inspection or maintenance. Some of the widely used industries are:

1. Oil and gas industries

2. Petrochemical industries

3. Marine industries

The type of raw materials

This flange may include carbon steel, stainless steel, alloy steel or other high quality metals. In general, the choice of raw materials depends on factors such as working conditions, pressure, temperature and environment. Some of the available items are:

1. Carbon Steel: ASTM A105, A350 LF2

2. Stainless Steel: A182 F304/F304L/F316/F316L/F321

3. Alloy Steel: ASTM A182, GR F1, F11, F22, F5, F9, F91

Contact our specialists in the sales unit for advice, order and purchase of your desired product and inquire about the price.

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Lap Joint Flange standards

This flange is produced based on different requirements and standards, which include the following:

1. ASME B16.5 standard

2. ASME B16.47 standard

3. API 605 standard

4. EN 1092-1 standard

Advantages and disadvantages

Advantages:

1. It is possible to connect to pipes and equipment with different thicknesses.

2. It is possible to carry out inspection, repair and maintenance operations easily.

3. Due to their compatibility and flexibility, they are suitable for all types of piping systems.

Disadvantages:

1. It requires high precision in the installation and implementation of welding operations.

2. It needs enough space to perform welding operations

Conclusion

Finally, it must be said that Lap Joint Flange is an effective and economical connection method that is used in various industries. This type of connector provides the possibility of connecting parts with different thicknesses and the possibility of carrying out maintenance operations easily. However, it requires floor space, high precision in installation and welding operation, which is one of the disadvantages of this type of flanges.

Sales department (Central):

| Phone number | |

|---|---|

| +9858-37217753-5 | sales@azinforge.com |

Sales department (Tehran):

| Phone number | |

|---|---|

| +9821-44443106 | commercial@azinforge.com |

Sales department (Mashhad):

| Phone number | |

|---|---|

| +9851-37597237 | commercial2@azinforge.com |

Follow AzinForge on LinkedIn and get access to our latest developments and projects in the field of forging and industrial design. Do not miss this opportunity and connect with us on this social network.